VIRTUAL SIMULATION TECHNOLOGY AND DYNAMIC RESPONSE ANALYSIS OF PE GAS PIPELINE UNDER VEHICLE LOAD

-

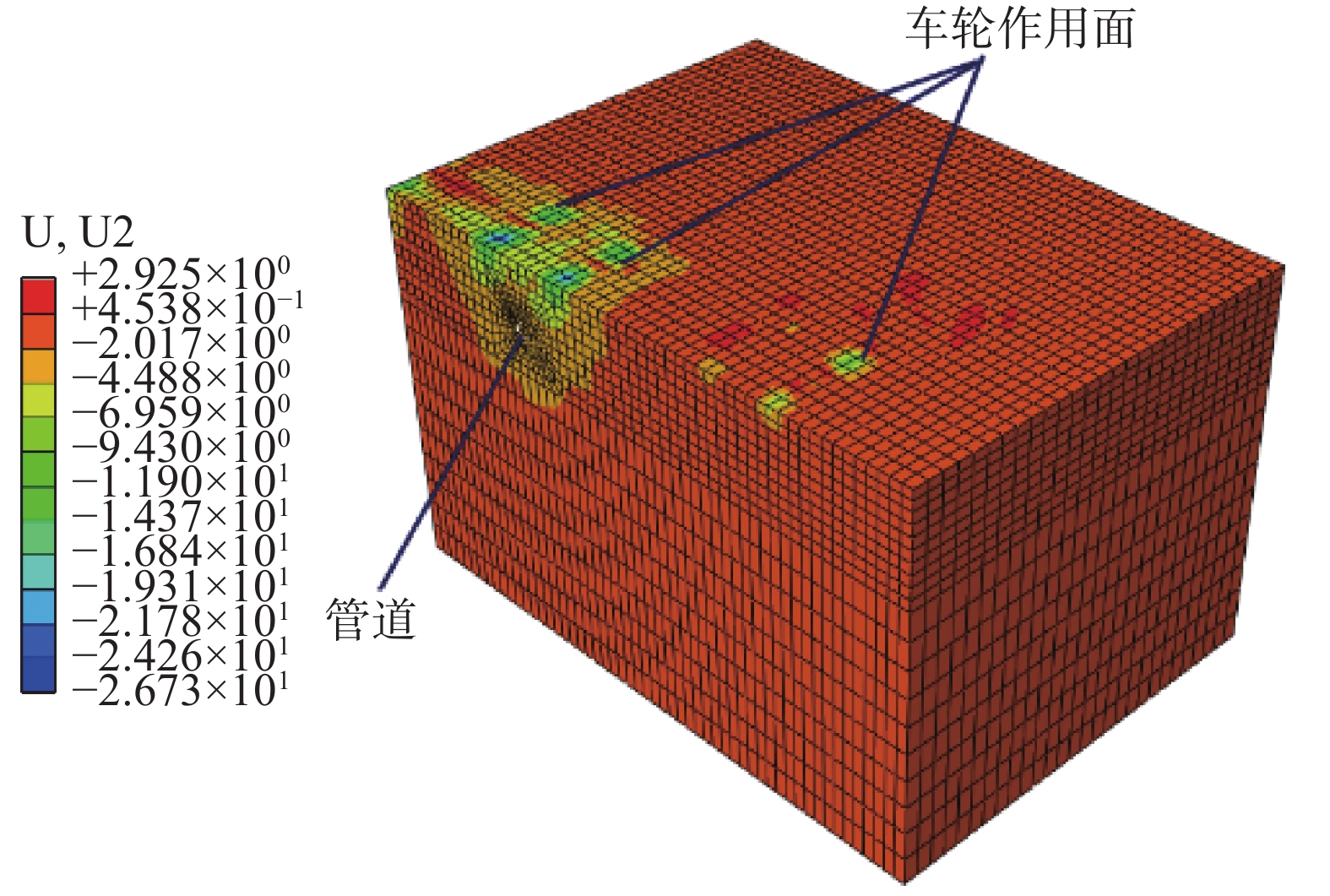

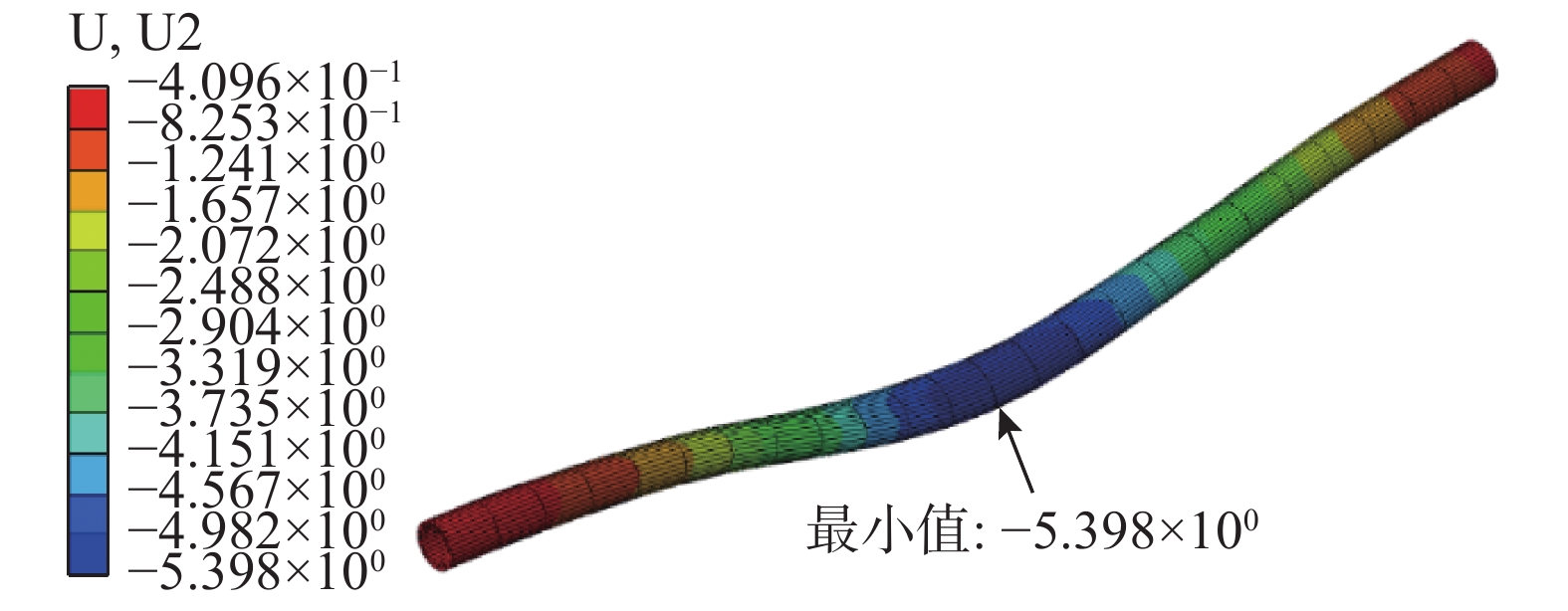

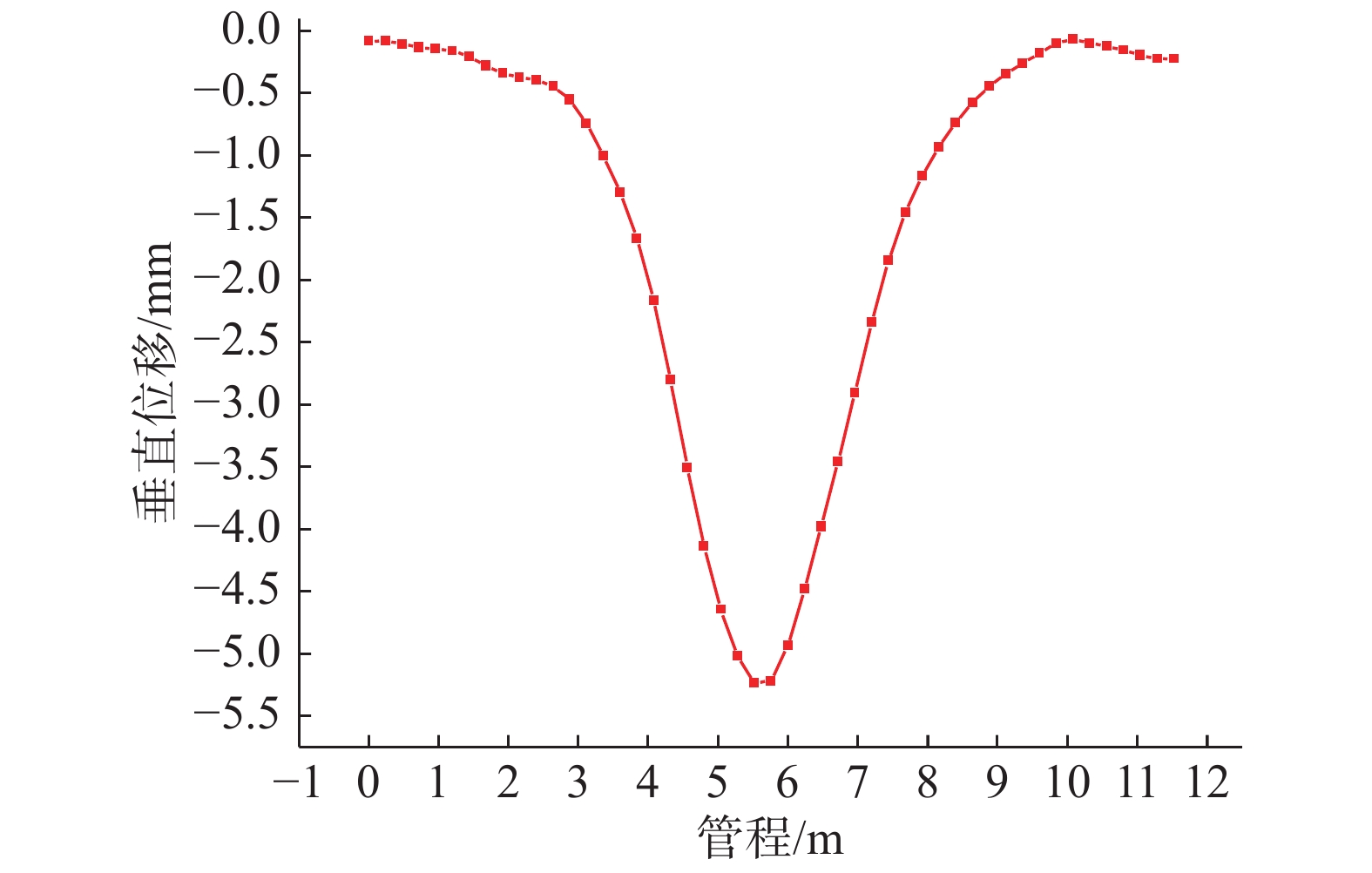

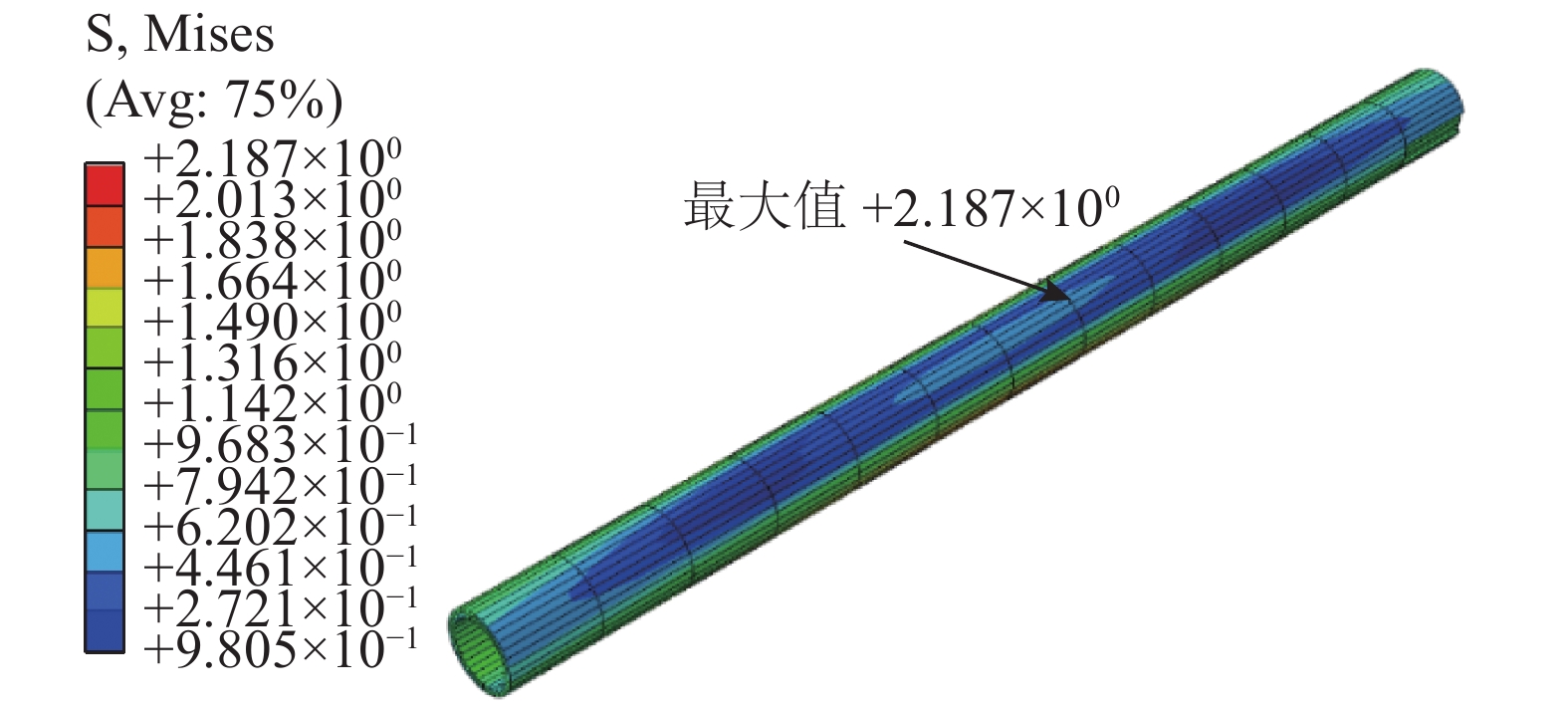

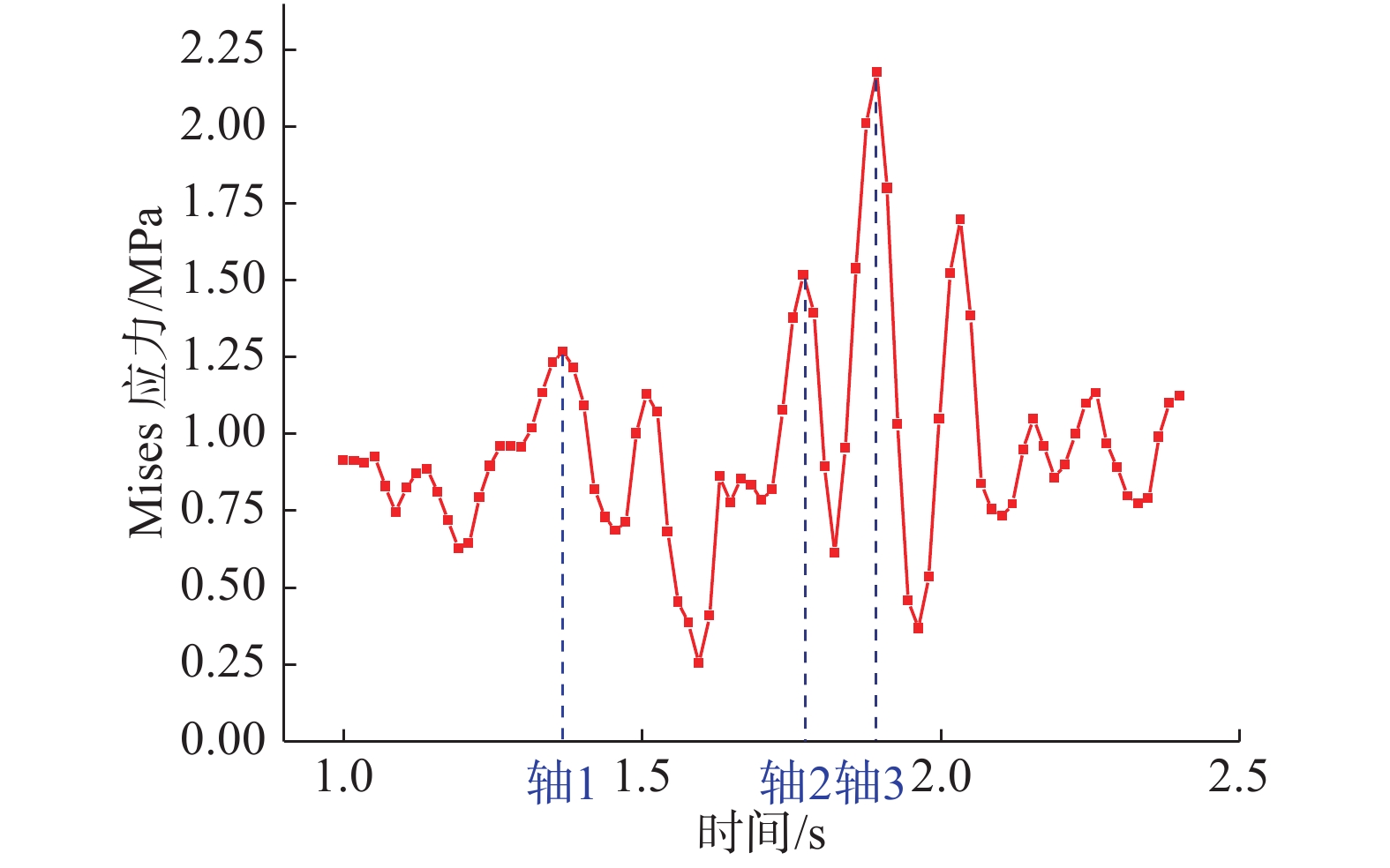

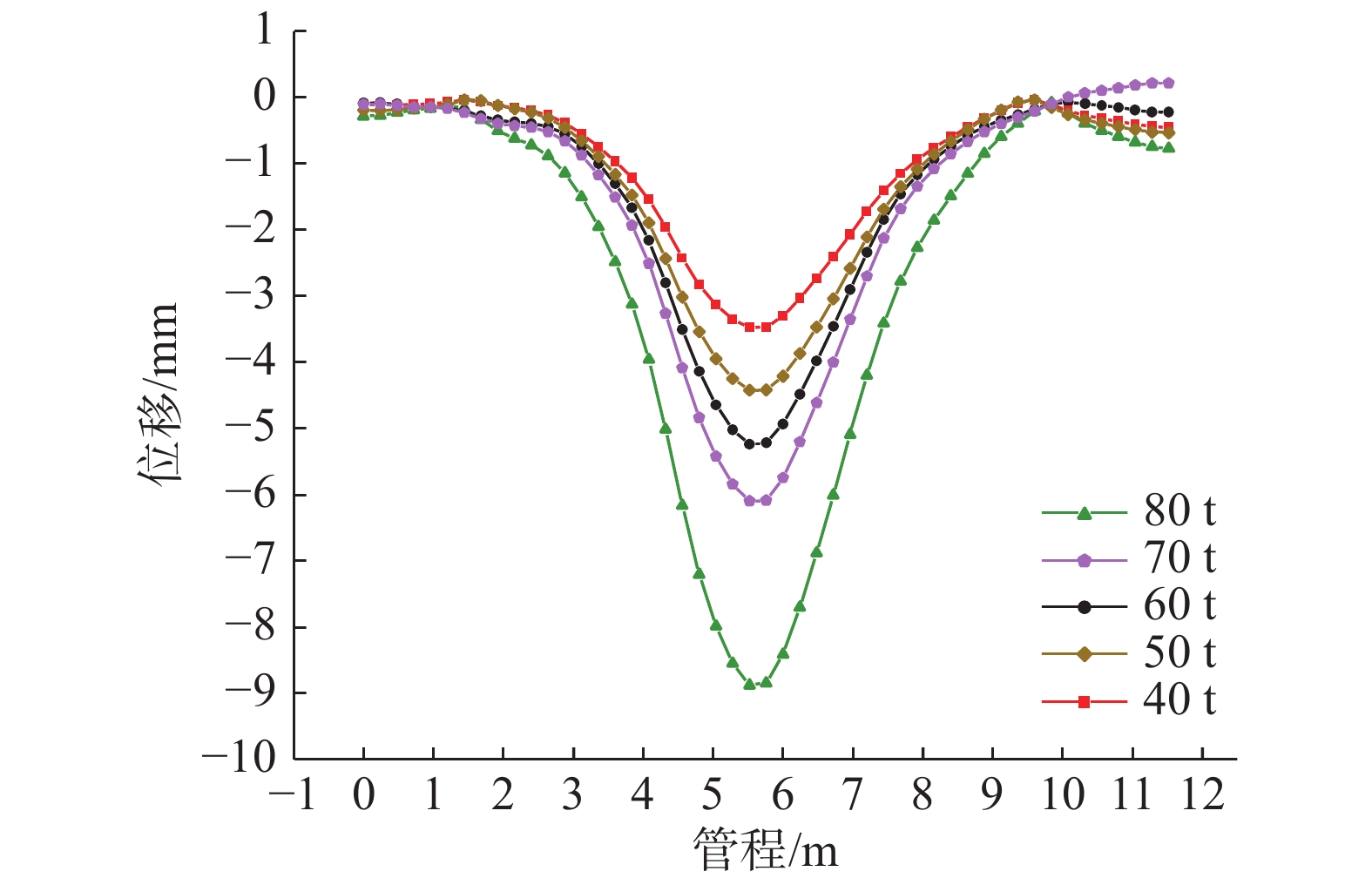

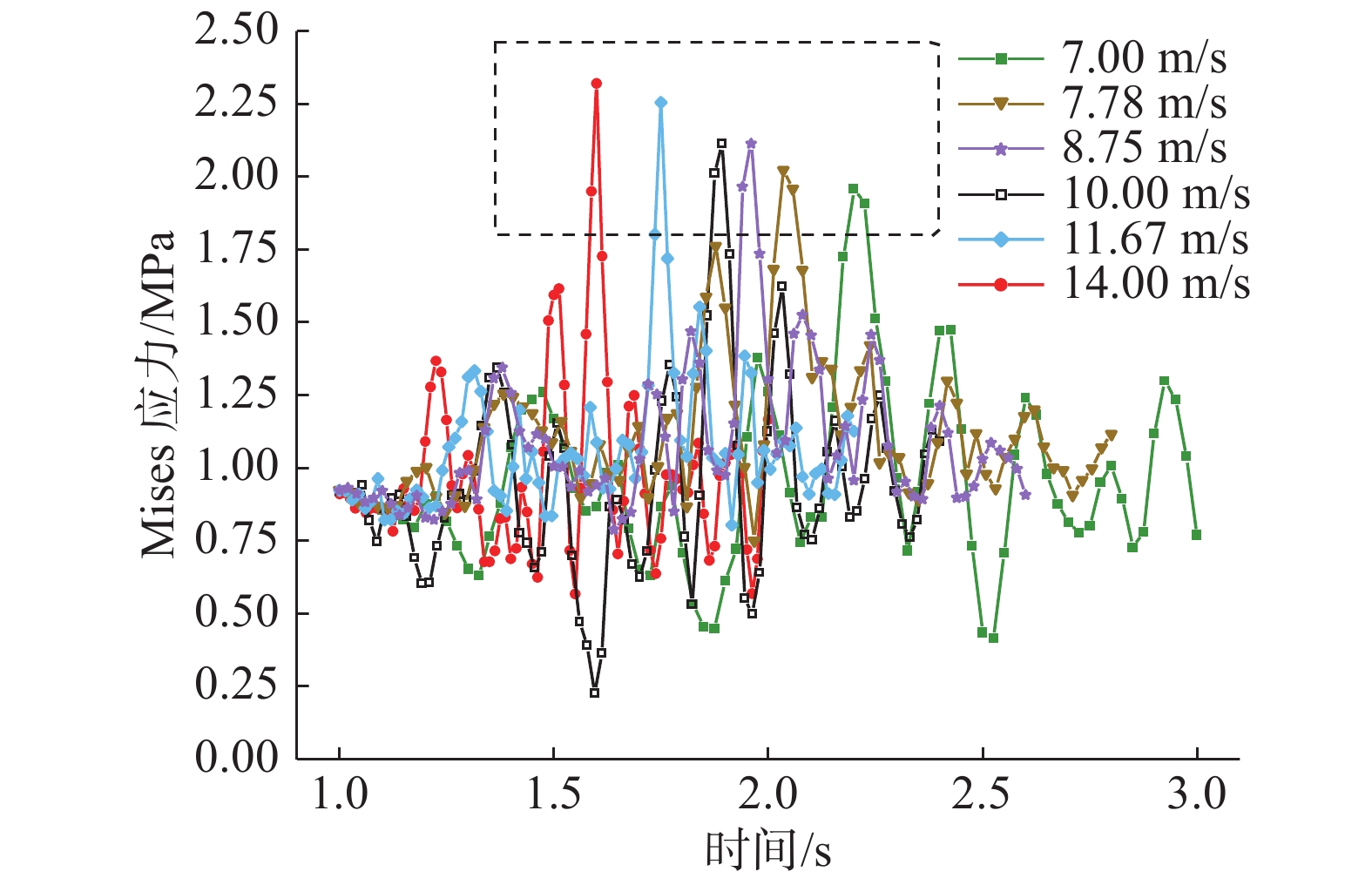

摘要: 当前,城镇燃气管道受车辆碾压造成的事故时有发生,为分析车辆载荷下PE燃气管道的动力响应,借助虚拟样机系统仿真软件ADAMS并结合有限元分析软件研究车辆的运动载荷及受载埋地PE燃气管道的力学特征。建立车辆-路面-土体-管道模型,根据实测值对仿真结果进行了验证。基于虚拟样机系统仿真提取的车辆动态载荷谱,分析PE燃气管道的动力响应过程,并开展不同车重、不同车速下埋地PE燃气管道的动力响应规律研究。结果表明:管体所受的应力及其位移量随着车重的增大而增大;管体所受应力随着车速的增大而增大,而其位移量随着车速的增大而减小。Abstract: In order to analyze the dynamic response of PE gas pipeline under vehicle loading, the virtual prototype system simulation software ADAMS and the finite element analysis software are used to study vehicle moving loads and the mechanical characteristics of buried PE gas pipeline under the loads. A vehicle-pavement-soil-pipeline model is established, and the simulation results are verified by measured values. Based on the vehicle dynamic load spectrum extracted by virtual prototype system simulation, the dynamic response process of PE gas pipeline is analyzed, and the dynamic response law of buried PE gas pipeline under different vehicle weights and speeds is studied. The results show that: the stress and displacement of the tube increases with the increase of vehicle weight; the stress on the pipe increases with the increase of the vehicle speed, and its displacement decreases with the increase of the vehicle speed.

-

-

表 1 重型卡车参数

Table 1 Heavy truck parameters

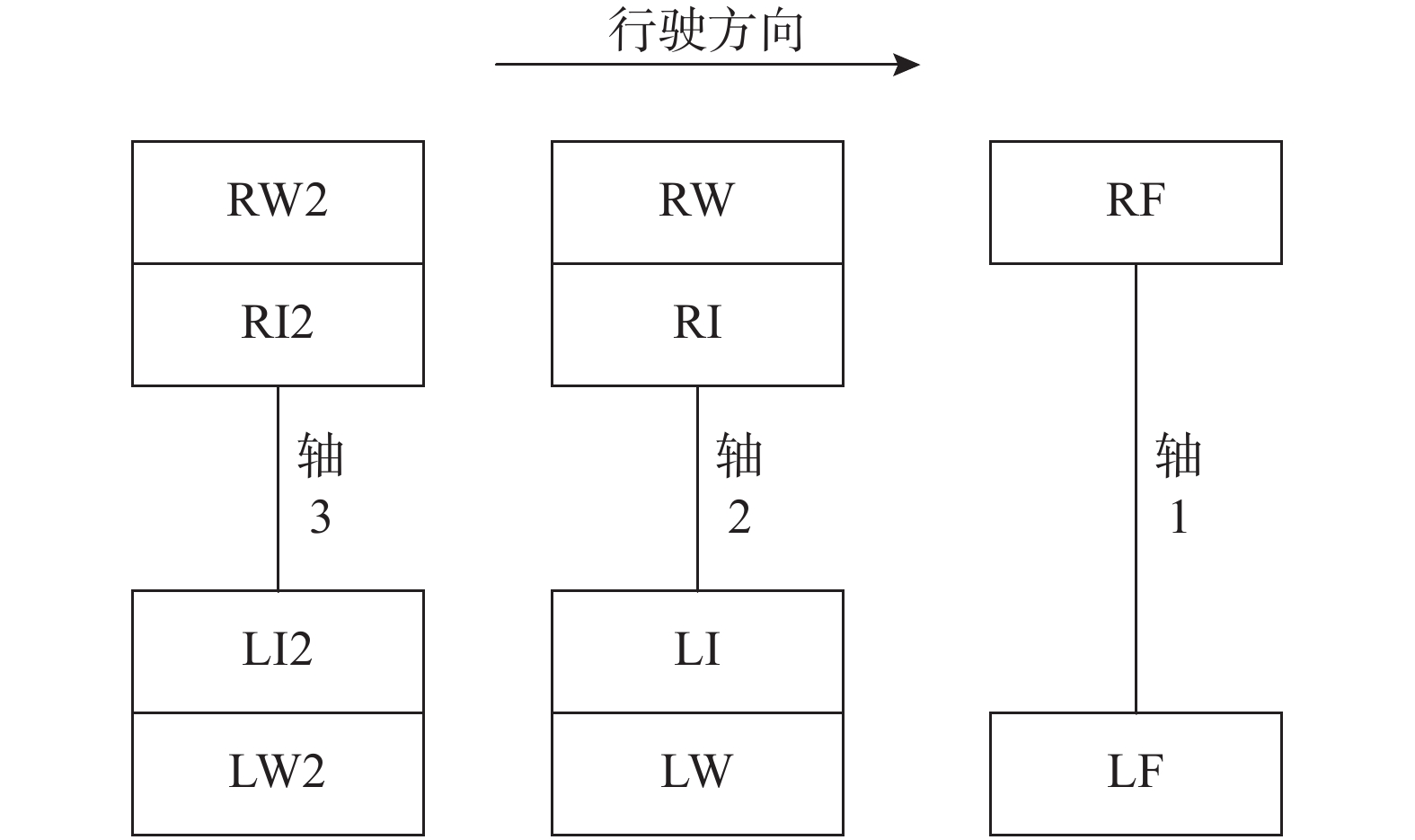

车辆参数 轮胎参数 自重/t 载重/t 轴数/个 轮压/MPa 轴距/mm 轮距/mm 12 <70 3 0.7~1.0 2400 2040/1880 表 2 各轮胎动载荷系数验证

Table 2 Verify the dynamic load coefficient of each tire

车轮编号 LF LI LI2 LW LW2 RF RI RI2 RW RW2 实测值[10] 1.37 1.37 1.37 1.37 1.37 1.37 1.37 1.37 1.37 1.37 计算值 1.274 1.376 1.272 1.447 1.241 1.222 1.436 1.391 1.277 1.280 误差 −0.070 0.005 −0.072 0.056 −0.094 −0.108 0.048 0.015 −0.068 −0.066 土体类型 密度ρ/(kg/m3) 弹性模量E1/MPa 泊松比μ 回填土 1869 20 0.4 摩擦角/(°) 流变应力比c 膨胀角φ/(°) − 36.5 1 0 − i 时间t/s 松弛模量E/MPa 剪切模量G/MPa 体积模量K/MPa 1 360 430.00 153.57 716.67 2 3600 320.00 114.29 533.33 3 36000 280.00 100.00 466.67 4 360000 250.00 89.59 416.67 i 松弛时间t/s 相对剪切模量gi 相对体积模量ki 1 360 0.3807 0.3947 2 3600 0.0858 0.0713 3 36000 0.0631 0.0723 4 360000 0.0515 0.0470 表 6 管-土模型验证

Table 6 Pipe-soil model validation

土体深度/m 模拟值/MPa 实测值/MPa[13] 误差/(%) 0.5 0.2225 0.2151 3.44 1.0 0.1342 0.1457 −7.89 1.5 0.0867 0.0886 −2.14 2.0 0.0294 0.0295 −0.33 表 7 不同车重下管道的最大位移和最大应力

Table 7 Maximum displacement and maximum stress of different vehicle weight under pipeline

车重/t 最大位移/mm 最大位移时刻/s 最大应力/MPa 最大应力时刻/s 40 3.655 0.7875 1.841 0.8925 50 4.599 0.7875 2.041 0.8925 60 5.398 0.7875 2.178 0.8925 70 6.265 0.7875 2.284 0.8925 80 9.109 0.7875 2.916 0.8750 表 8 不同车速下管道的最大位移和最大应力

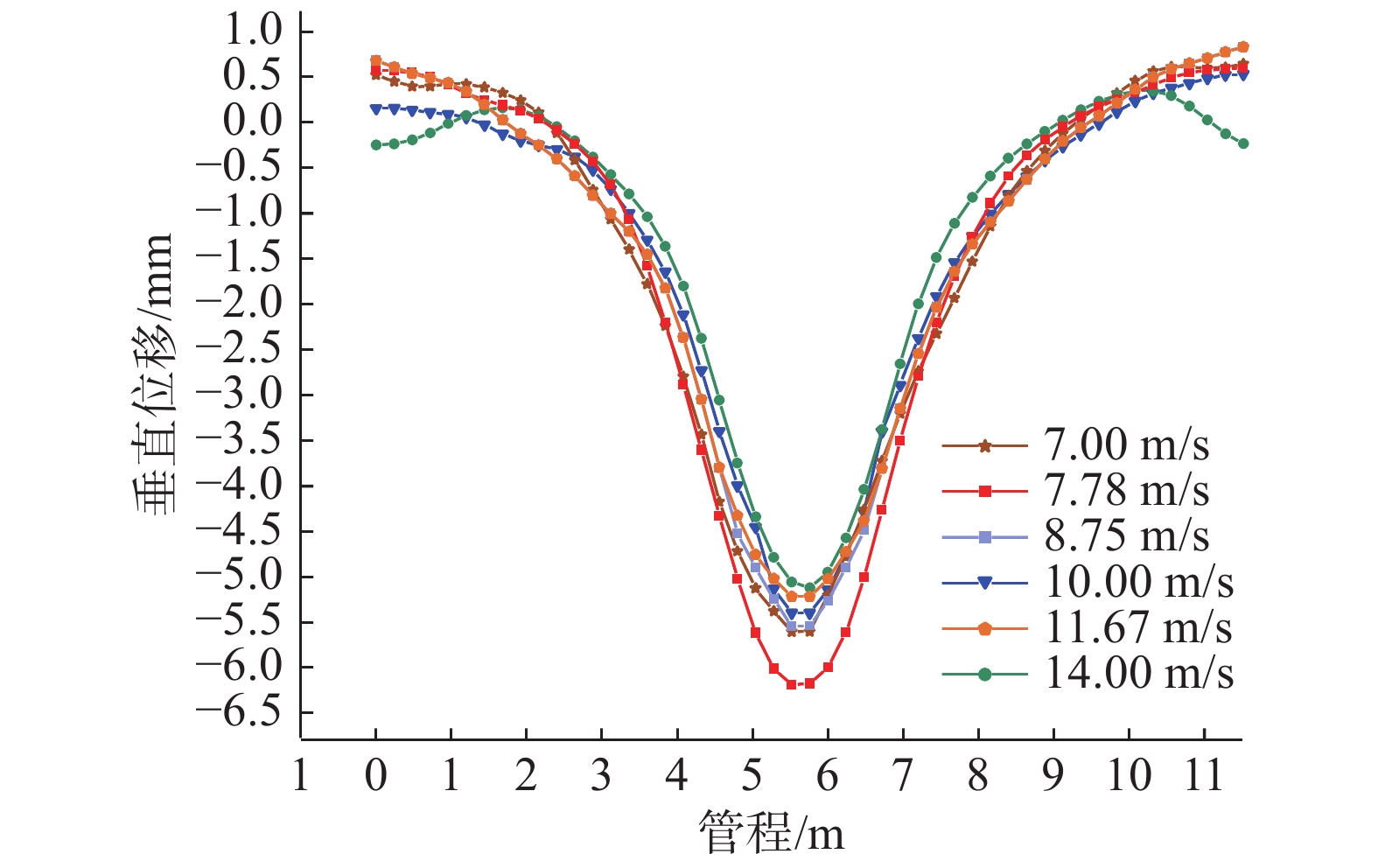

Table 8 Maximum displacement and maximum stress of pipeline under different speed

车速m/s 最大位移/mm 最大位移时刻/s 最大应力/MPa 最大应力时刻/s 7.00 6.195 1.0250 1.997 1.2000 7.78 5.604 0.9675 2.021 1.0350 8.75 5.543 0.8600 2.113 0.9600 10.00 5.398 0.7875 2.178 0.8925 11.67 5.220 0.7200 2.254 0.7500 14.00 5.139 0.5250 2.323 0.6000 -

[1] 朱荣全, 阮艳灵, 秦立臣, 等. PE燃气管道力学失效模式分析[J]. 化学工程与装备, 2017(3): 43 − 44, 67. Zhu Rongquan, Ruan Yanling, Qin Lichen, et al. Mechanical failure mode analysis of gas pipeline [J]. Chemical Engineering & Equipment, 2017(3): 43 − 44, 67. (in Chinese)

[2] 卢正, 王长柏, 付建军, 等. 交通荷载作用下公路路基工作区深度研究[J]. 岩土力学, 2013, 34(2): 316 − 321, 352. Lu Zhen, Wang Changbai, Fu Jianjun, et al. Deep study on roadbed working area under traffic load [J]. Rock and Soil Mechanics, 2013, 34(2): 316 − 321, 352. (in Chinese)

[3] Oyen M L, Cook R F. Load-displacement behavior during sharp indentation of viscous-elastic-plastic materials [J]. Journal of Materials Research, 2003, 18(1): 139 − 150. doi: 10.1557/JMR.2003.0020

[4] 陈锦裕, 朱志彬, 杨晓翔. PE80燃气管道的应力松弛模型与实验验证[J]. 中国塑料, 2016, 30(4): 93 − 98. Chen jinyu, Zhu zhibin, Yang Xiaoxiang. Stress relaxation model and experimental verification of PE80 gas pipeline [J]. China Plastics, 2016, 30(4): 93 − 98. (in Chinese)

[5] 郑绵彬, 张玲. 交通载荷作用下聚乙烯燃气管道失效率分析[J]. 塑料工业, 2009, 37(2): 39 − 42. doi: 10.3321/j.issn:1005-5770.2009.02.011 Zheng Mianbin, Zhang Lin. Failure rate analysis of polyethylene gas pipeline under traffic load [J]. China Plastics Industry, 2009, 37(2): 39 − 42. (in Chinese) doi: 10.3321/j.issn:1005-5770.2009.02.011

[6] 董冬冬, 王非, 张亚军, 等. 交通载荷作用下HDPE管道附加弯矩变化规律研究[J]. 地下空间与工程学报, 2016, 12(增刊 1): 80 − 88, 99. Dong Dongdong, Wang Fei, Zhang Yajun, et al. Study on the Changing Mechanism of Additional Bending Moment in Buried HDPE Pipes under Traffic Loading [J]. Chinese Journal of Underground Space and Engineering, 2016, 12(Suppl 1): 80 − 88, 99. (in Chinese)

[7] 李明阳, 陈国华. 交通载荷作用下埋地聚乙烯燃气管道的有限元分析[J]. 塑料工业, 2009, 37(9): 30 − 33. doi: 10.3321/j.issn:1005-5770.2009.09.008 Li Mingyang, Chen Guohua. Finite element analysis of buried polyethylene gas pipeline under traffic load [J]. China Plastics Industry, 2009, 37(9): 30 − 33. (in Chinese) doi: 10.3321/j.issn:1005-5770.2009.09.008

[8] 卢培纪, 王福明. 某型车路面冲击载荷作用下瞬态动力分析[J]. 机械研究与应用, 2014, 27(1): 19 − 20, 26. Lu Peiji, Wang Fuming. Vehicles transient dynamic analysis under the impact loading [J]. Mechanical Research & Application, 2014, 27(1): 19 − 20, 26. (in Chinese)

[9] 赵兰英, 鲁植雄, 侯占峰. 路面不平度的分形分级参数研究[J]. 交通与计算机, 2008, 26(6): 158 − 161. Zhao Yinglan, Lu Zhixiong, Hou Zhanfeng. Study on fractal grading parameters of road roughness [J]. Transportation and Computers, 2008, 26(6): 158 − 161. (in Chinese)

[10] 董忠红, 吕彭民. 高等级路面上的车辆动载荷[J]. 长安大学学报(自然科学版), 2010, 30(1): 95 − 99. Dong Zhonghong, Lu Pengmin. Dynamic load of vehicle on high-class pavement [J]. Journal of Chang'an University (Natural Science), 2010, 30(1): 95 − 99. (in Chinese)

[11] 周立国, 姚安林, 徐涛龙, 等. 挖掘载荷下燃气PE管道损伤分析[J]. 中国安全科学学报, 2017, 27(3): 59 − 64. Zhou Liguo, Yao Anlin, Xu Taolong, et al. Damage analysis of urban gas PE pipeline under excavation load [J]. China Safety Science Journal, 2017, 27(3): 59 − 64. (in Chinese)

[12] 左建东. 含缺陷燃气聚乙烯管道的安全评定数值分析 [D]. 北京: 北京交通大学, 2017. Zuo Jiandong. Numerical Analysis of Safety Assessment of Gas Polyethylene Pipes with Defects [D]. Beijing: Beijing Jiaotong University, 2017. (in Chinese)

[13] 余红伟, 倪友伟, 姚士洪. 车辆载荷碾压作用下管道的安全性测试与分析[J]. 石油工程建设, 2009, 35(3): 15 − 19, 5. doi: 10.3969/j.issn.1001-2206.2009.03.004 Yu Hongwei, Ni Youwei, Yao Shihong. Safety test and analysis of pipeline under rolling load of vehicle [J]. Petroleum Engineering Construction, 2009, 35(3): 15 − 19, 5. (in Chinese) doi: 10.3969/j.issn.1001-2206.2009.03.004

-

期刊类型引用(3)

1. 田伟,李旭,孙赞. 高大模板支撑体系设计与施工控制策略研究. 工程技术研究. 2022(20): 203-205 .  百度学术

百度学术

2. 王永祥,张涛,王静怡,倪瑞远,曾愉,钟楚欣,韩子凡. 基于FAHP法的超高超重支模架施工风险识别及防范研究. 建筑施工. 2020(07): 1326-1329+1347 .  百度学术

百度学术

3. 陆萍,陈盈,李云开,吴海军. 基于雅申理论的混凝土模板侧压力计算模型及实验研究. 工程力学. 2019(08): 201-209 .  本站查看

本站查看

其他类型引用(2)

下载:

下载: