EXPERIMENTAL STUDY ON SEISMIC PERFORMANCE OF ENERGY DISSIPATION AND POSITION LIMITATION STEEL BRACE AND STRUCTURE SEISMIC VULNERABILITY ANALYSIS

-

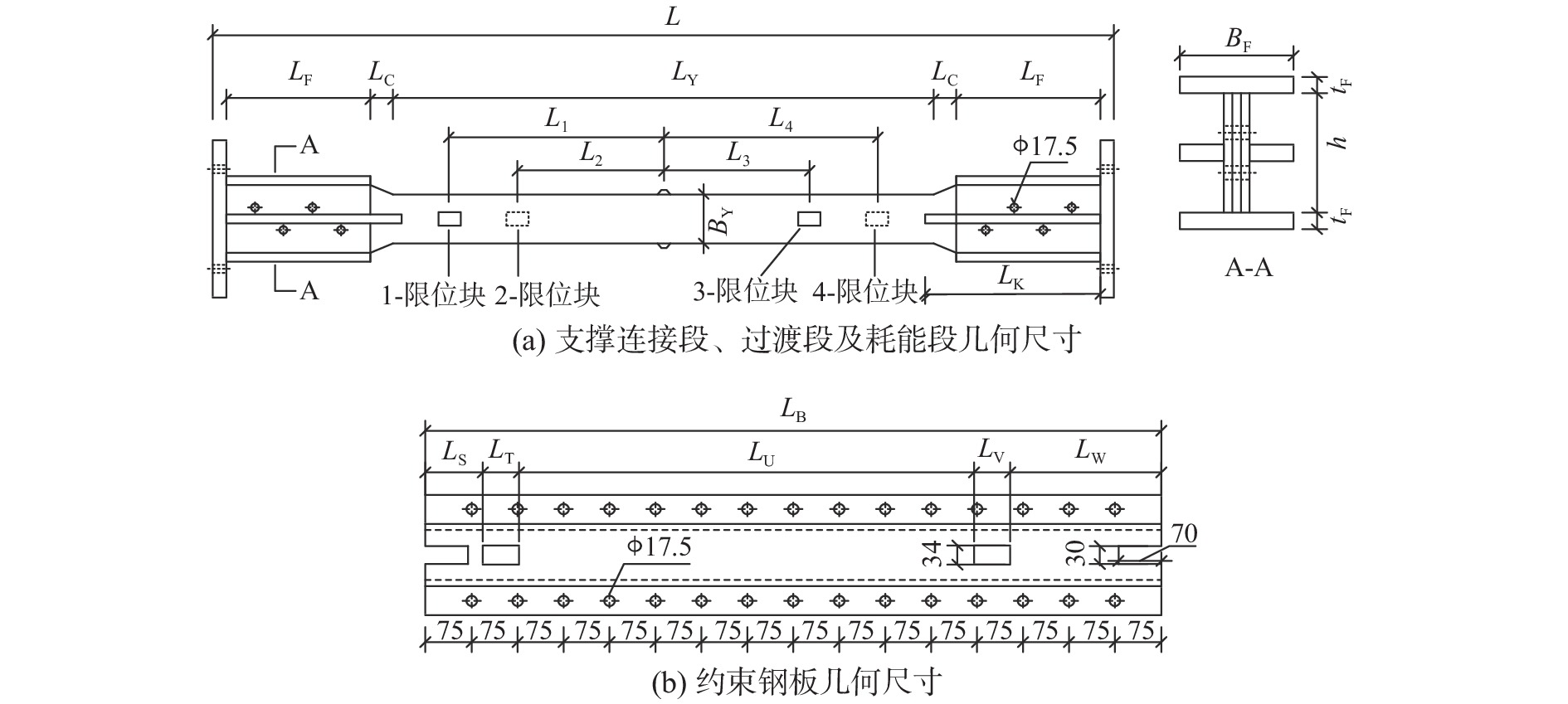

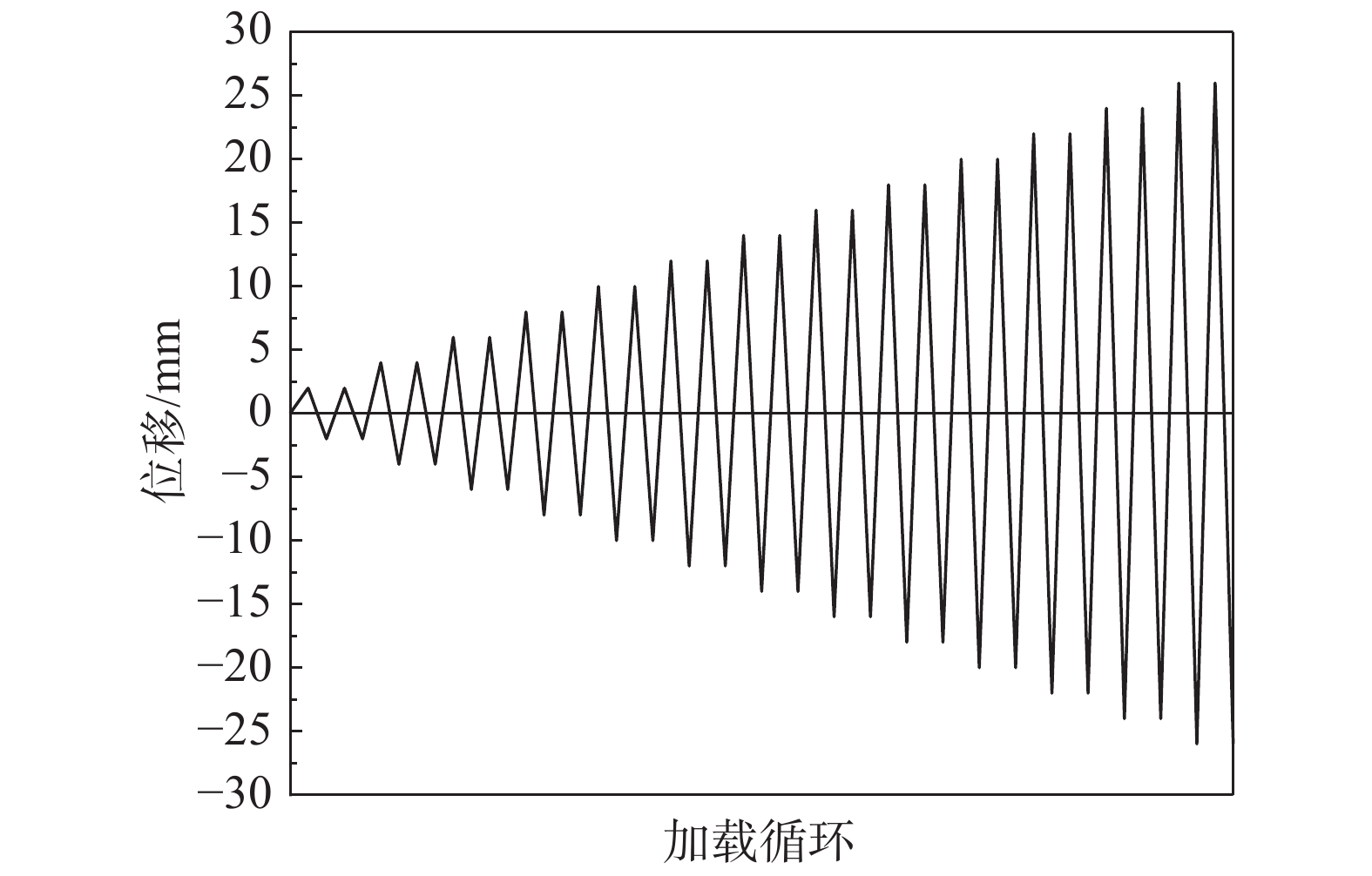

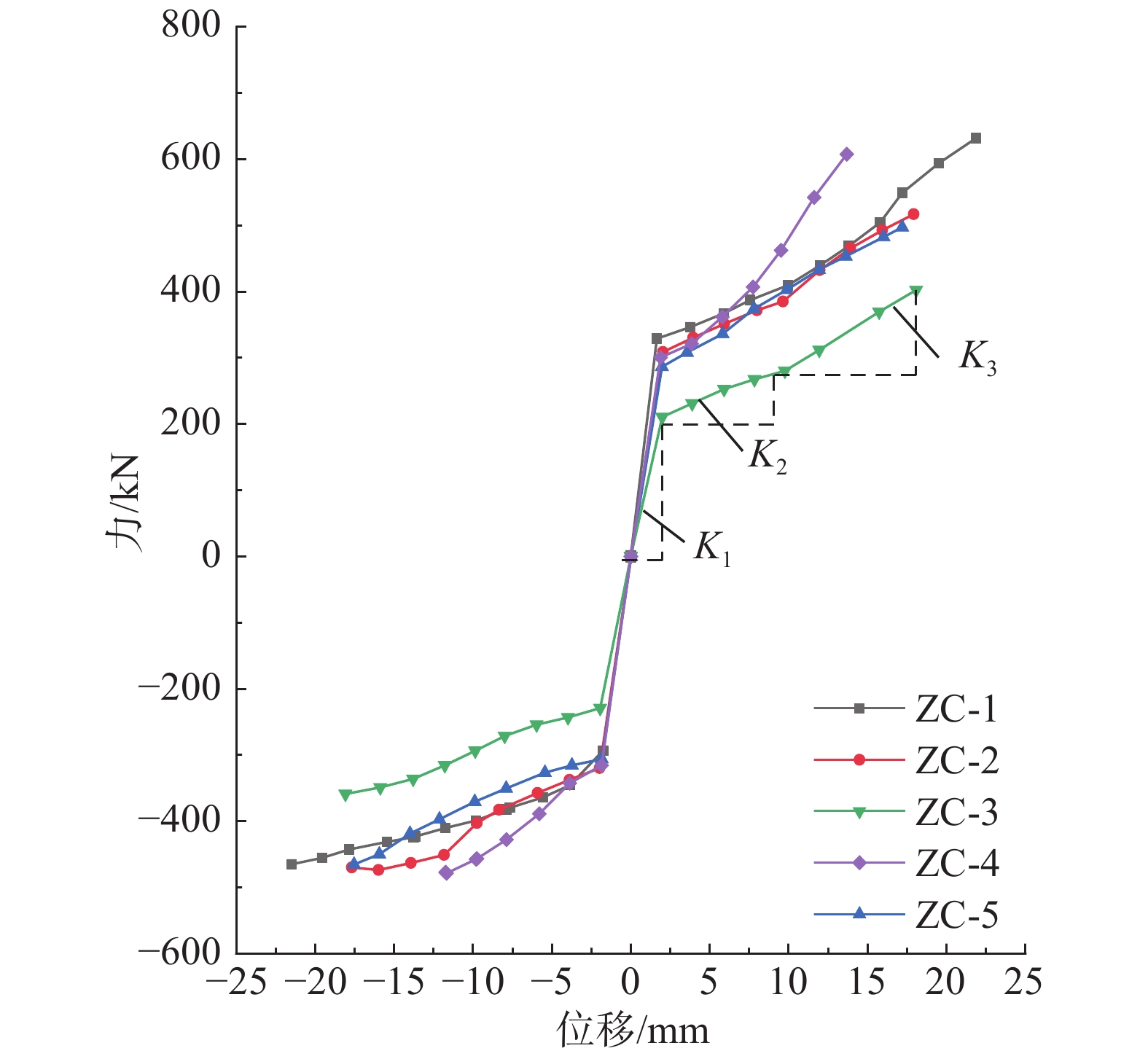

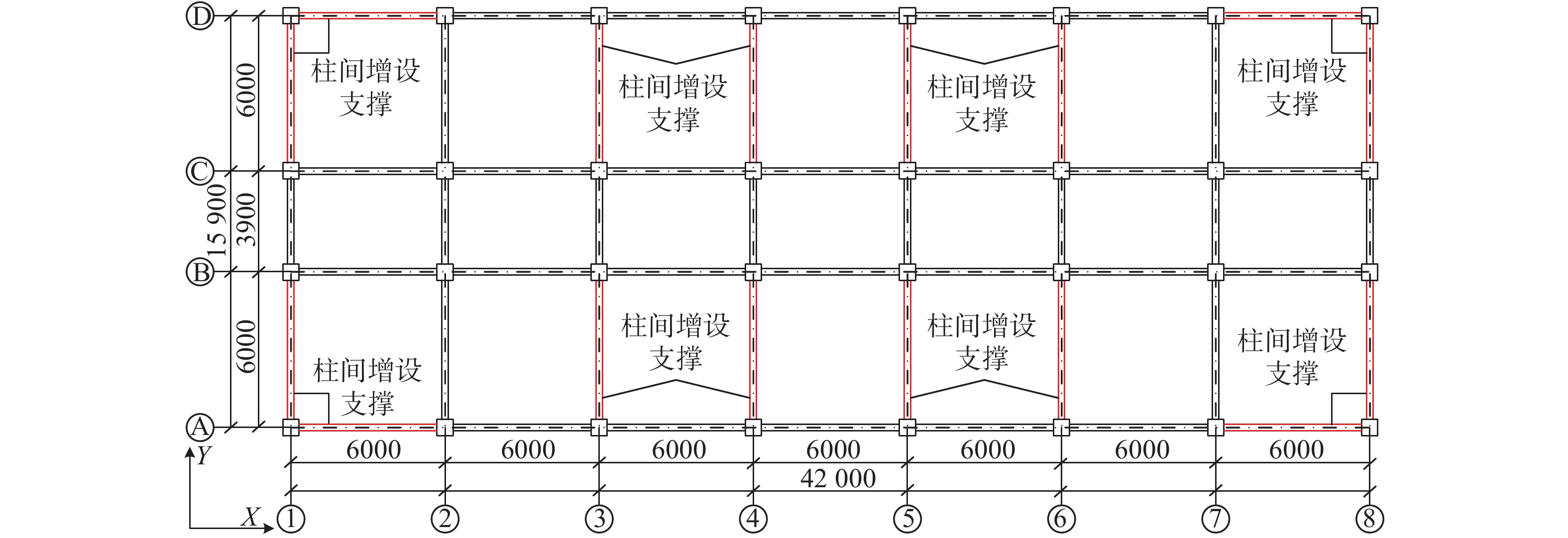

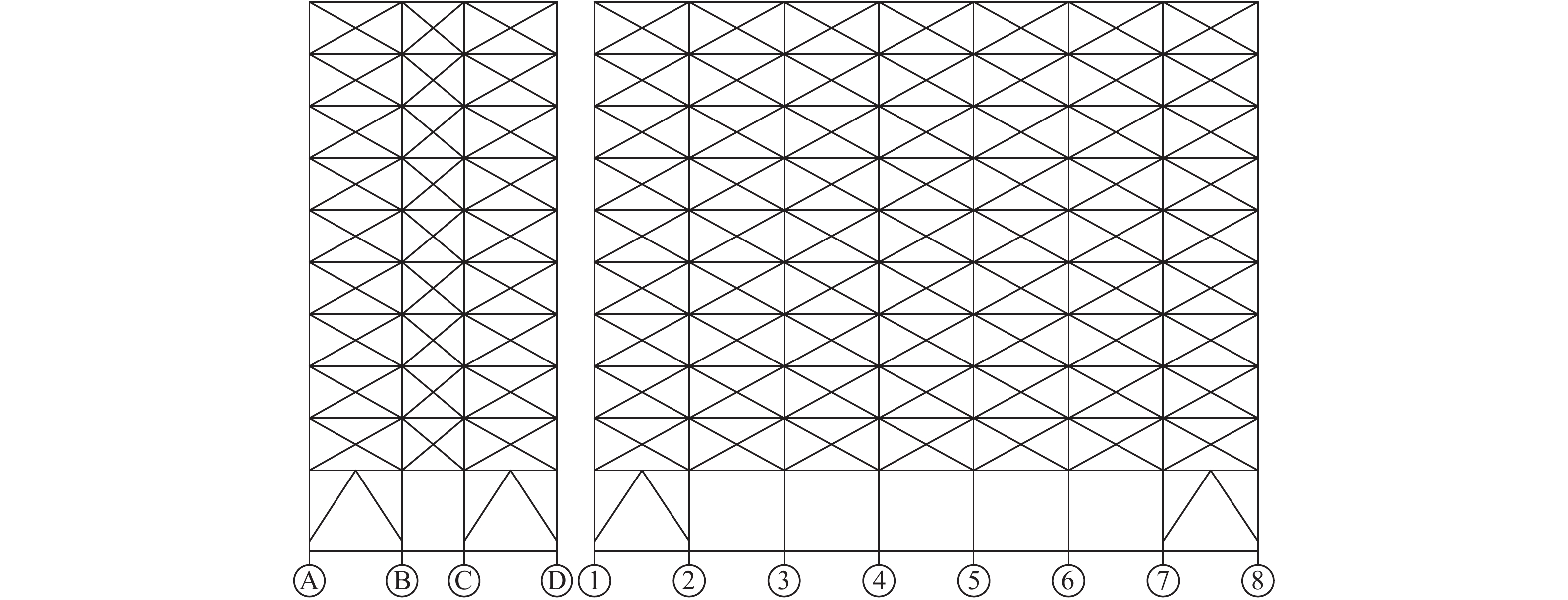

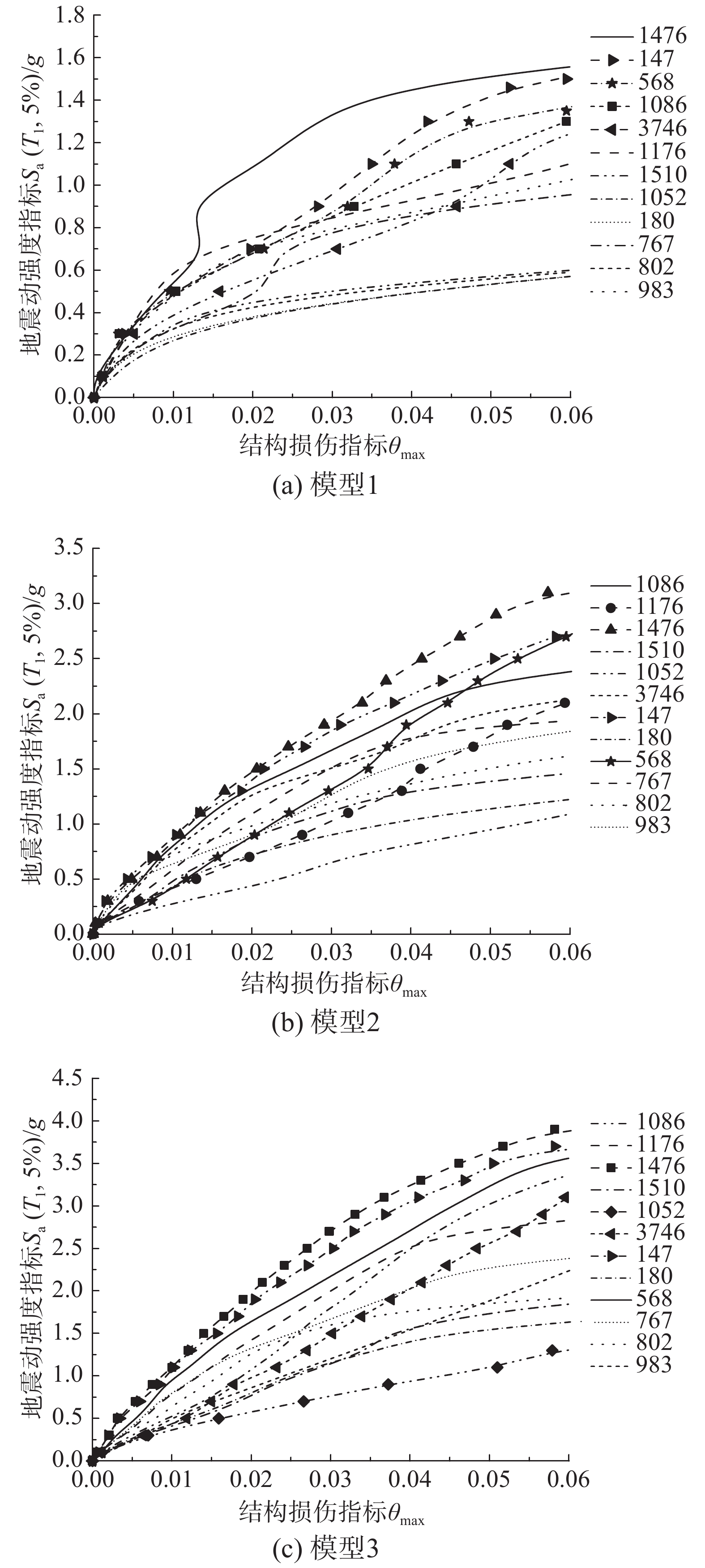

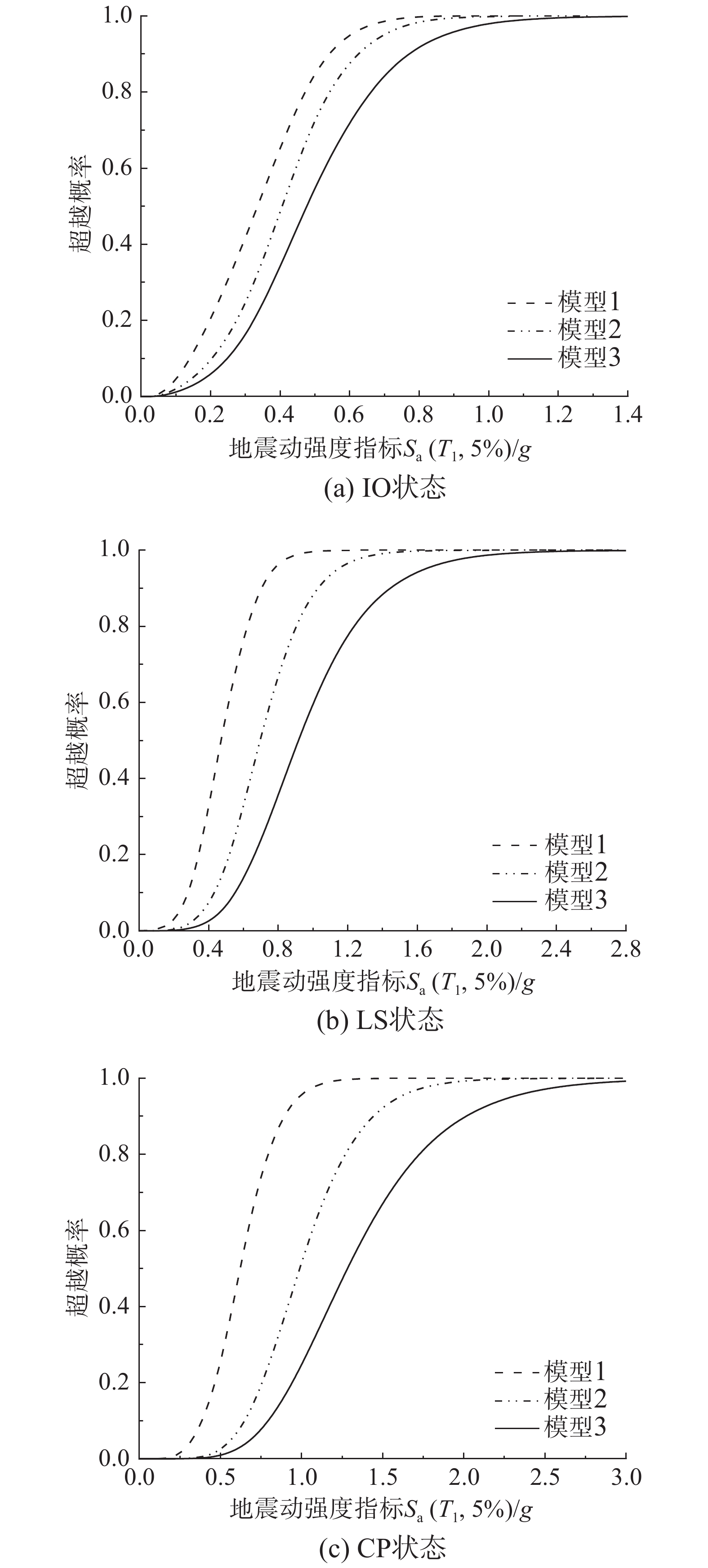

摘要: 该文提出一种消能限位型钢支撑以期改善建筑结构抗震性能,设计了5个钢支撑,设计参数为限位位移、限位块数量、钢芯截面尺寸及长度。通过低周往复加载试验对5个钢支撑的破坏特征、滞回特性、骨架曲线和刚度等抗震性能进行了研究。基于IDA分析评估了含钢支撑框架结构模型的抗地震倒塌性能。结果表明:该钢支撑构造合理,滞回性能稳定;增设限位块后可发挥限位作用,并可提供较大的附加刚度;限位块数量和截面尺寸以及其与支撑工作段连接面焊缝的刚度影响附加刚度的提升程度;该文提出的钢支撑各阶段刚度计算公式所得结果与试验值符合较好,可为钢支撑设计提供参考;设置含有限位块的消能限位型钢支撑结构的倒塌储备系数提高,有利于改善底层柔性结构的抗倒塌能力。Abstract: A kind of energy dissipation and position limitation type steel brace is proposed to improve the seismic performance of a building structure. Five steel braces are designed, and the limitation displacement, limitation block number, steel core section size and length are chosen as the design parameters. Based on the test study, the characteristics including the failure mode, hysteresis loops behavior, skeleton curves, and stiffness are demonstrated. The seismic collapse resistance of steel braced frame structures is evaluated through IDA analysis. The results show that: the steel brace structure is reasonable with stable hysteretic performance, and the position limitation block could play a limiting role and provide greater additional stiffness. The number and section size of the position limitation block and the weld stiffness of the joint surface with the steel core affect the lifting degree of the additional stiffness. The calculation results of the stiffness formulas presented are in a good agreement with the experimental values, which can provide a reference for the practical design of steel braces. The collapse reserve coefficient of this type of steel braces with position limitation blocks is increased, beneficial to improve the collapse resistance of soft first storey building.

-

-

表 1 试件设计参数

Table 1 Design parameters of specimen

试件

编号钢芯截面

尺寸/mm2钢芯

长度/mm限位

应变/(%)限位

位移

d1/mm限位

位移

d2/mm限位

位移

d3/mm限位

位移

d4/mmZC-1 110×10 1200 0.0 − − − − ZC-2 110×10 1200 1.0 4.5 3 3 4.5 ZC-3 80×10 1200 1.0 4.5 3 3 4.5 ZC-4 110×10 800 1.0 3.0 2 2 3.0 ZC-5 110×10 1200 2.0 9.0 6 6 9.0 表 2 支撑连接段、过渡段及耗能段几何尺寸

Table 2 Geometric dimension of support core unit

试件编号 连接段 耗能段 过渡段长

LC/mm支撑总长

L/mmL1/mm L2/mm L3/mm L4/mm 长度

LF/mm翼缘宽

BF/mm翼缘厚

tF/mm侧向加劲

肋长LK/mm水平加劲

板高h/mm长度

LY/mm宽度

BY/mmZC-1 320 135 20 390 190 1200 110 50 2000 − − − − ZC-2 320 135 20 390 190 1200 110 50 2000 450 300 300 450 ZC-3 320 135 20 390 160 1200 80 50 2000 450 300 300 450 ZC-4 270 135 20 320 190 800 110 50 1500 300 200 200 300 ZC-5 320 135 20 390 190 1200 110 50 2000 450 300 300 450 注:L1~L4分别为相应限位块中心到钢芯中间截面的距离。 表 3 约束钢板几何尺寸

Table 3 Geometric dimension of restrained steel plate

试件编号 LB/mm LS/mm LT/mm LU/mm LV/mm LW/mm ZC-1 1200 − − − − − ZC-2 1200 120.5 59 692.5 56 272 ZC-3 1200 120.5 59 692.5 56 272 ZC-4 800 72 56 445 54 173 ZC-5 1200 116 68 685 62 269 表 4 钢材的主要力学性能

Table 4 Mechanical properties of steel

用途 钢号 板厚/

mm屈服

强度/MPa极限

强度/MPa断后

伸长率/(%)强屈比 钢芯 Q235 10 386 531 39 1.38 约束钢板 Q235 20 337 450 33 1.34 表 5 支撑各阶段刚度值

Table 5 Stiffness values of the brace

试件编号 试验值 理论计算值 相对误差/(%) K1/(kN/mm) K2/(kN/mm) K3/(kN/mm) K1/(kN/mm) K2/(kN/mm) K3/(kN/mm) K1 K2 K3 ZC1 182.6 6.2 − 176.0 5.7 − 3.8 8.7 − ZC2 160.8 6.1 14.4 176.0 5.7 13.8 −8.6 7.0 4.3 ZC3 118.4 4.5 11.3 129.9 4.1 12.2 −8.9 9.8 −7.4 ZC4 164.8 5.9 15.0 176.0 5.7 13.8 −6.3 3.5 8.7 ZC5 159.2 6.0 9.3 176.0 5.7 9.7 −9.5 5.2 −4.1 表 6 钢支撑几何参数

Table 6 Geometric parameters of steel bracing

钢芯 约束钢板 限位块 连接段长度/mm 过渡段长度/mm 支撑总长度/mm 长度/mm 宽度/mm 厚度/mm 长度/mm 宽度/mm 厚度/mm 长度/mm 宽度/mm 厚度/mm 4460 440 40 4460 720 60 200 120 60 400 200 5660 表 7 近断层地震动记录

Table 7 Near fault ground motion records

序号 RSN 台站 震级 断层距/km PGA/g 脉冲周期/s 1 1476 TCU029 7.62 28.04 0.16 5.285 2 1176 YPT150 7.51 1.38 0.32 4.949 3 1510 TCU075 7.62 0.89 0.33 4.998 4 983 JGB022 6.69 5.43 0.57 3.535 5 147 G02140 6.53 8.47 0.26 0.35 6 767 G03090 6.93 12.23 0.37 2.639 7 802 STG090 6.93 7.58 0.33 4.571 8 1052 PKC360 6.69 5.26 0.43 0.728 9 3746 CBF360 7.01 16.44 0.48 1.967 10 568 GIC090 5.80 2.14 0.71 0.805 11 1086 SYL360 6.69 1.74 0.84 2.436 12 180 E05230 6.53 1.76 0.38 4.130 表 8 不同性态水平的最大层间位移角限值[27]

Table 8 Maximum interlaminar displacement angle limits at different performance levels

结构性能水平 性能状态描述 楼层最大层间位移角/(%) 立即使用(IO) 结构轻度破坏 1 生命安全(LS) 结构遭受一定的破坏 2 防止倒塌(CP) 结构遭受严重破坏 4 表 9 结构倒塌储备系数CMR

Table 9 Structural collapse reserve factor CMR

模型编号 Sa(T1)50%/g Sa(T1) / g CMR 模型1 0.60 0.39 1.54 模型2 1.0 0.42 2.38 模型3 1.25 0.44 2.84 -

[1] 李宗超, 陈学良, 吴健, 等. 台湾地区花莲地震(Ms6.5)工程地震动参数特征分析[J]. 建筑结构, 2018, 48(增刊 2): 308 − 313. Li Zongchao, Chen Xuelang, Wu Jian, et al. Engineering seismic parameters characteristic analysis of Hualian earthquake (Ms6.5) inTaiwan region [J]. Building Structure, 2018, 48(Suppl 2): 308 − 313. (in Chinese)

[2] Kun Ji, Ruizhi Wen, Yefei Ren, et al. Nonlinear seismic site response classification using K-means clustering algorithm: Case study of the September 6, 2018 Mw6.6 Hokkaido Iburi-Tobu earthquake, Japan [J]. Soil Dynamics and Earthquake Engineering, 2020, 128: 105907.1 − 105907.14.

[3] 葛庆子, 马华. 带纤维混凝土耗能器底层柔性结构的抗震研究[J]. 工程抗震与加固改造, 2012, 34(5): 20 − 26. doi: 10.3969/j.issn.1002-8412.2012.05.004 Ge Qingzi, Ma Hua. Aseismic study of flexible structures with fiber reinforced concrete dampers [J]. Earthquake Resistant Engineering and Retrofitting, 2012, 34(5): 20 − 26. (in Chinese) doi: 10.3969/j.issn.1002-8412.2012.05.004

[4] 李振宝, 马华, 闫维波, 等. 带RC耗能器-限位斜撑框架抗震性能研[J]. 建筑结构, 2008(11): 65 − 67. Li Zhenbao, Ma Hua, Yan Weibo, et al. Seismic behavior of frame with RC dampers and lock-up braces [J]. Building Structure, 2008(11): 65 − 67. (in Chinese)

[5] 曹万林, 刘建民, 王东增, 等. 异型柱框架结构底层支撑合理设置研究[J]. 地震工程与工程振动, 1997(1): 77 − 82. Cao Wanlin, Liu Jianmin, Wang Dongzeng, et al. Research on the reasonable setting of bottom support of special-shaped column frame structure [J]. Earthquake Engineering and Engineering Vibration, 1997(1): 77 − 82. (in Chinese)

[6] Rahai A R, Alinia M M. Performance evaluation and strengthening of concrete structures with composite bracing members [J]. Construction and Building Materials, 2008, 10(22): 2100 − 2110.

[7] 武娜, 高向宇, 李自强, 等. 用带防屈曲支撑的内嵌式钢框架加固混凝土框架的试验研究[J]. 工程力学, 2013, 30(12): 189 − 198. doi: 10.6052/j.issn.1000-4750.2012.08.0618 Wu Na, Gao Xiangyu, Li Ziqiang, et al. Experimental study on reinforced concrete frames retrofitted with in-filled steel frames and connected brbs [J]. Eengineering Mechanics, 2013, 30(12): 189 − 198. (in Chinese) doi: 10.6052/j.issn.1000-4750.2012.08.0618

[8] 陆伟东, 蓝宗建, 刘伟庆. 阻尼支撑控制结构薄弱层的设计方法研究[J]. 工程抗震与加固改造, 2011, 33(2): 57 − 62. doi: 10.3969/j.issn.1002-8412.2011.02.010 Lu Weidong, Lan Zhongjian, Liu Weiqing. Design method of damped bracings to control the structure with weak story [J]. Earthquake Resistant Engineering and Retrofitting, 2011, 33(2): 57 − 62. (in Chinese) doi: 10.3969/j.issn.1002-8412.2011.02.010

[9] 欧进萍, 马宁, 吴斌. 一字形内芯全钢防屈曲支撑设计方法[J]. 工程力学, 2012, 29(10): 137 − 141, 148. doi: 10.6052/j.issn.1000-4750.2011.01.0017 Ou Jinping, Ma Ning, Wu Bin. Design of all-stell buckling restrained brace with a flat plate core [J]. Eengineering Mechanics, 2012, 29(10): 137 − 141, 148. (in Chinese) doi: 10.6052/j.issn.1000-4750.2011.01.0017

[10] 郭彦林, 姜子钦, 王小安, 等. 双矩管装配式防屈曲支撑约束刚度取值研究[J]. 工程力学, 2015, 32(4): 22 − 32. doi: 10.6052/j.issn.1000-4750.2014.04.0322 Guo Yanlin, Jiang Ziqin, Wang Xiaoan, et al. Study on restraing stiffness of double rectaangular tube assembled buckling-restrained beace [J]. Eengineering Mechanics, 2015, 32(4): 22 − 32. (in Chinese) doi: 10.6052/j.issn.1000-4750.2014.04.0322

[11] 姜子钦, 郭彦林, 张博浩, 等. 双矩管装配式防屈曲支撑设计理论研究[J]. 工程力学, 2015, 32(6): 41 − 51, 61. doi: 10.6052/j.issn.1000-4750.2014.06.0502 Jiang Ziqin, Guo Yanlin, Zhang Bohao, et al. Theretical study on design methods for double rectangular tube assembled buckling-restrained beaces [J]. Eengineering Mechanics, 2015, 32(6): 41 − 51, 61. (in Chinese) doi: 10.6052/j.issn.1000-4750.2014.06.0502

[12] 杨璐, 卫璇, 施刚, 等. LY315钢屈曲约束支撑耗能性能试验研究[J]. 工程力学, 2019, 36(1): 200 − 206. doi: 10.6052/j.issn.1000-4750.2017.11.0879 Yang Lu, Wei Xuan, Shi Gang, et al. Experiment on energy dissipation performance of LY315 steel buckling-restrained braces [J]. Eengineering Mechanics, 2019, 36(1): 200 − 206. (in Chinese) doi: 10.6052/j.issn.1000-4750.2017.11.0879

[13] Iwata M, Kato T, Wada A. Buckling-restrained braces as hysteretic dampers [C]// Proceedings of Third International Conference on Behavior of Steel Structures in Seismic Areas. Montreal, Canada: Rotterdam and Brookfield, 2000: 3338.

[14] Nip K H , Gardner L, Elghazouli A Y. Cyclic testing and numerical modelling of carbon steel and stainless steel tubular bracing members [J]. Engineering Structures, 2010, 32(2): 424 − 441. doi: 10.1016/j.engstruct.2009.10.005

[15] Oda H, Usami T. Fabricating buckling-restrained braces from existing Hsectionbracing members: Experimental study [J]. Journal of Structural Engineering, JSCE, 2010, 56(A): 499 − 510.

[16] 邓雪松, 纪宏恩, 周云, 等. 开孔板式屈曲约束支撑拟静力滞回性能试验研究[J]. 土木工程学报, 2015, 48(1): 49 − 55. Deng Xuesong, Ji Hongen, Zhou Yun, et al. Quasi-static cyclic tests on hysteretic behavior of a perforating plate buckling restrained brace [J]. China Civil Engineering Journal, 2015, 48(1): 49 − 55. (in Chinese)

[17] 周云, 龚晨, 钟根全, 等. 开孔参数对装配式开孔钢板屈曲约束支撑性能影响研究[J]. 建筑结构学报, 2018, 39(增刊 2): 328 − 335. Zhou Yun, Gong Chen, Zhong Genquan, et al. Performance of perforated steel-plate assembled buckling-restrained brace with different perforated parameters [J]. Journal of Building Structures, 2018, 39(Suppl 2): 328 − 335. (in Chinese)

[18] 万金国, 杨凡, 李文峰, 等. 双屈服点免断裂屈曲约束支撑性能试验与数值模拟[J]. 建筑结构, 2013, 43(17): 105 − 108. Wan Jinguo, Yang Fan, Li Wenfeng, et al. Experiment research and mechanical simulation of BRB with double yield points and non-fracture [J]. Building Structure, 2013, 43(17): 105 − 108. (in Chinese)

[19] 赵堃宇, 闫维明, 贾洪, 等. 销钉式防屈曲支撑性能试验研究[J]. 工程抗震与加固改造, 2013, 35(5): 120 − 126. doi: 10.3969/j.issn.1002-8412.2013.05.020 Zhao Kunyu, Yan Weiming, Jia Hong, et al. Experimental research on performance of pin type BRB [J]. Earthquake Resistant Engineering and Retrofitting, 2013, 35(5): 120 − 126. (in Chinese) doi: 10.3969/j.issn.1002-8412.2013.05.020

[20] 周云, 钟根全, 陈清祥, 等. 不同构造钢板装配式屈曲约束支撑性能试验研究[J]. 土木工程学报, 2017, 50(12): 9 − 17. Zhou Yun, Zhong Genquan, Chen Qingquan, et al. Experimental study on hysteretic performance of steel-plate assembled buckling-restrained braces with different constructional details [J]. China Civil Engineering Journal, 2017, 50(12): 9 − 17. (in Chinese)

[21] 徐龙河, 孙雨生, 要世乾, 等. 装配式自复位耗能支撑恢复力模型与试验验证[J]. 工程力学, 2019, 36(6): 119 − 127. doi: 10.6052/j.issn.1000-4750.2018.04.0249 Xu Longhe, Sun Yusheng, Yao Shiqian, et al. Restoring force model and experimental verification of an assembled self-centering energy dissipation brace [J]. Eengineering Mechanics, 2019, 36(6): 119 − 127. (in Chinese) doi: 10.6052/j.issn.1000-4750.2018.04.0249

[22] 严红, 潘鹏, 王元清, 等. 一字形全钢防屈曲支撑耗能性能试验研究[J]. 建筑结构学报, 2012, 33(11): 142 − 149. Yan Hong, Pan Peng, Wang Yuanqing, et al. Experimental study of buckling-restrained braces with in-line steel core plate encased in double web wide flange steel outer unit [J]. Journal of Building Structures, 2012, 33(11): 142 − 149. (in Chinese)

[23] 陈奎. 可置换低屈服点金属钢节点的构造及特点 [D]. 北京: 北京工业大学, 2016: 37 − 39. Chen Kui. Seismic behavior and structure damage analysis of the replaceable beam-column connection with low yield point steel [D]. Beijing: Beijing University of Technology, 2016: 37 − 39. (in Chinese)

[24] Hashemi S A. Seismic evaluation of reinforced concrete buildings including effects of masonry infill walls [D]. Berkeley: University of California, 2007.

[25] Shome N. Probabilistic seismic demand analysis of nonlinear structures [D]. Stanford: Stanford University, 1999.

[26] Baker J W. Quantitative classification of near-fault ground motions using wavelet analysis [J]. Bulletin of Seismological Society of America, 2007, 97(5): 1486 − 1501. doi: 10.1785/0120060255

[27] FEMA. Prestandard and commentary for the seismic rehabilitation of buildings [M]. Washington, D.C.: Federal Emergency Management Agency, 2000.

[28] 任浩, 田勤虎, 张炜超, 等. 基于IDA方法的钢筋混凝土框架结构地震易损性分析[J]. 建筑结构, 2019, 49(增刊 2): 350 − 355. Ren Hao, Tian Qinhu, Zhang Weichao, et al. Seismic vulnerability analysis of reinforced concrete frame structure based on IDA method [J]. Building Structure, 2019, 49(Suppl 2): 350 − 355. (in Chinese)

[29] FEMA. HAZUS-MH technical manual [M]. Washington, D.C.: Federal Emergency Management Agency, 2003.

[30] Deierlein G G, Liel A B. ATC63 methodology for evaluating seismic collapse safety of archetype buildings [C]// Proceedings of ASCE-SEI Structures Congress, Vancouver, 2008.

-

期刊类型引用(5)

1. 邹云峰,卢玄东,阳劲松,周帅,何旭辉. 基于模态综合法和模态叠加法的密集模态结构响应重构. 工程力学. 2023(03): 54-64 .  本站查看

本站查看

2. 周星宇. 在线监测系统在危重桥梁运维的应用. 价值工程. 2023(14): 125-127 .  百度学术

百度学术

3. 邹云峰,卢玄东,阳劲松,何旭辉. 基于应变模态响应重构的损伤识别方法. 工程力学. 2022(09): 225-233 .  本站查看

本站查看

4. 杨振伟,周广东,伊廷华,李宏男. 基于分级免疫萤火虫算法的桥梁振动传感器优化布置研究. 工程力学. 2019(03): 63-70 .  本站查看

本站查看

5. 任鹏,周智,白石,欧进萍. 桁架结构疲劳监测的应变响应估计方法研究. 工程力学. 2018(09): 114-125 .  本站查看

本站查看

其他类型引用(6)

下载:

下载: