RESEARCH ON STIFFNESS OF HUB-SHAPE INLAY JOINT AND BEARING CAPACITY OF SINGLE-LAYER SPHERICAL RETICULATED SHELL

-

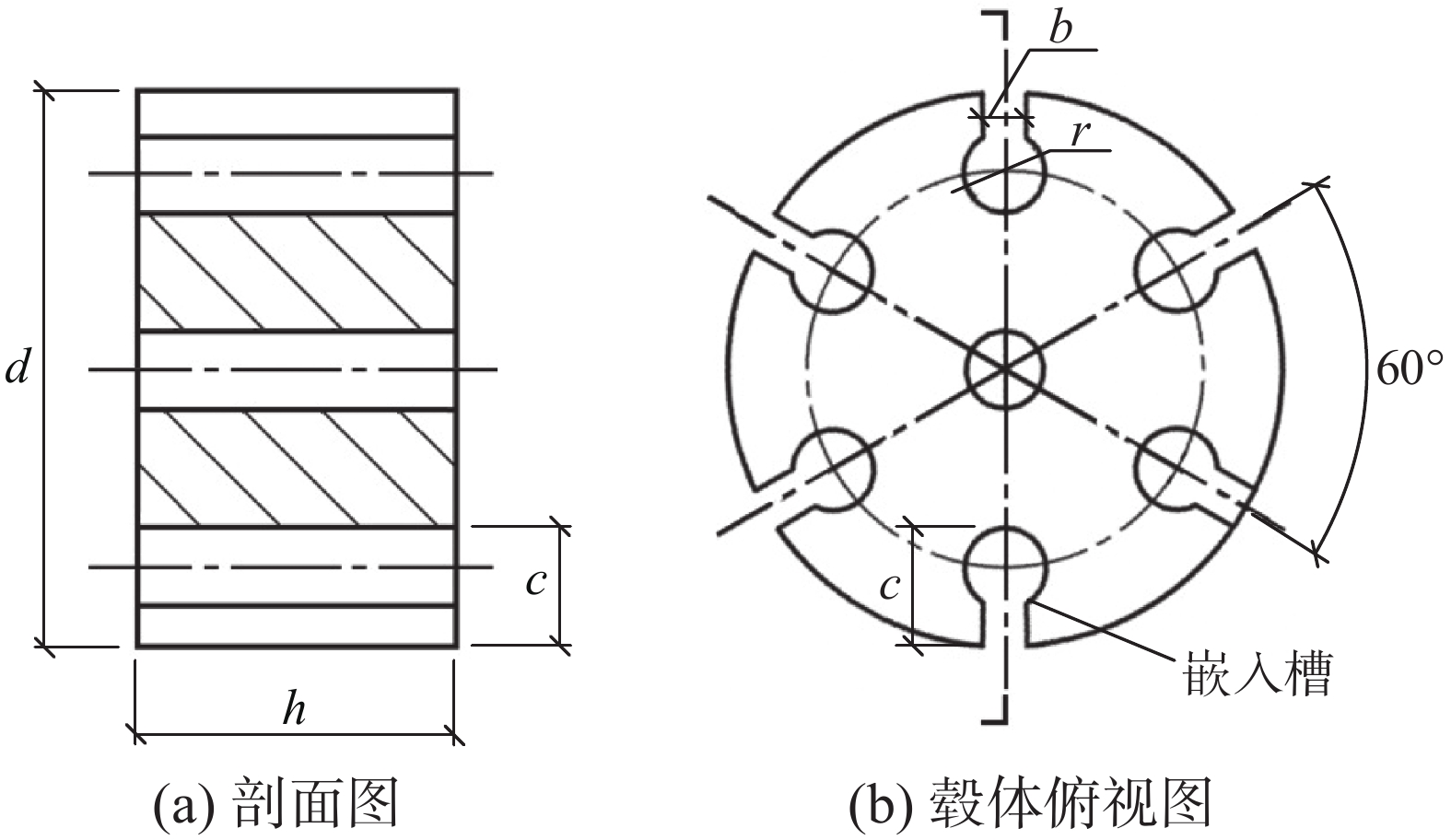

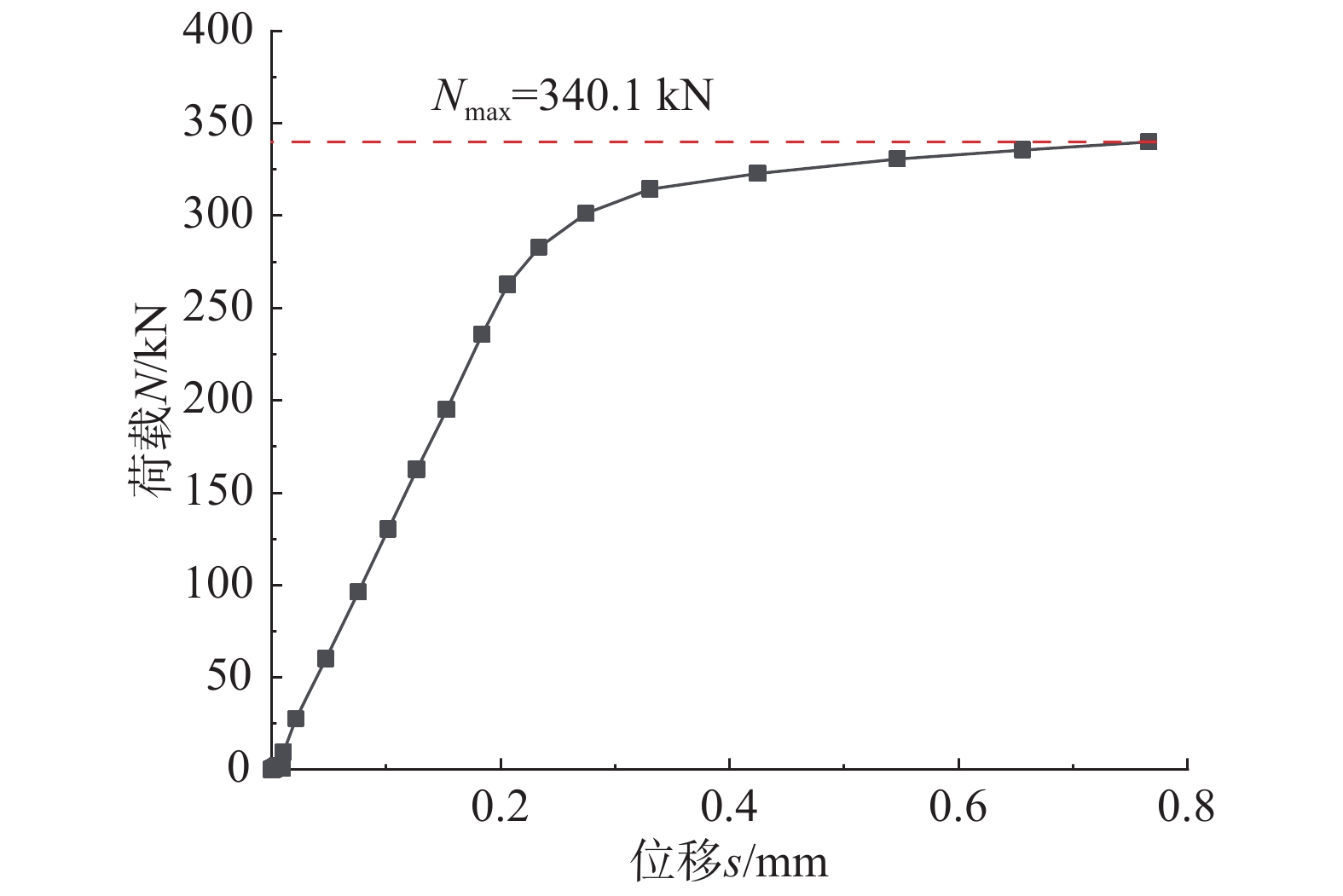

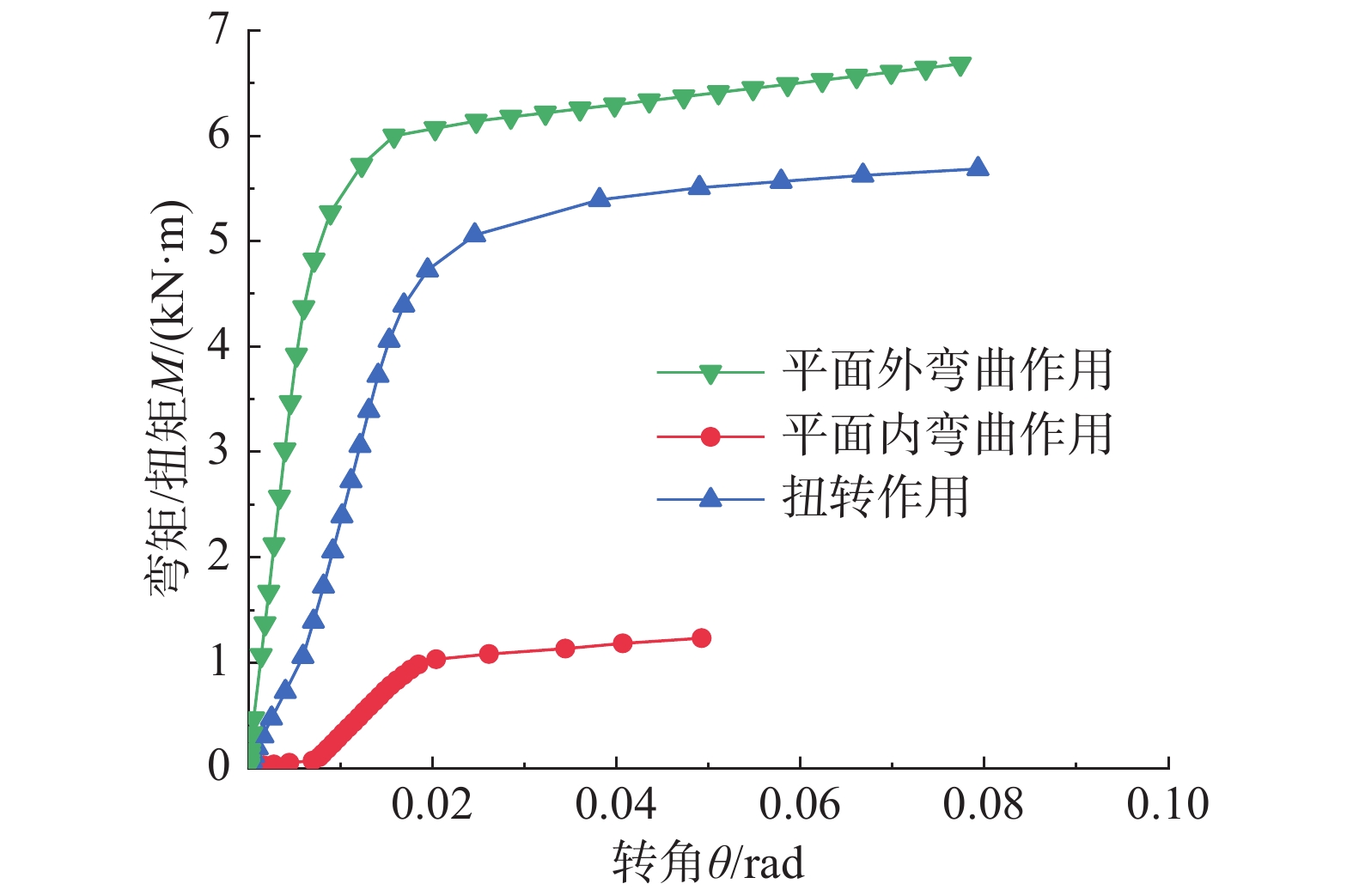

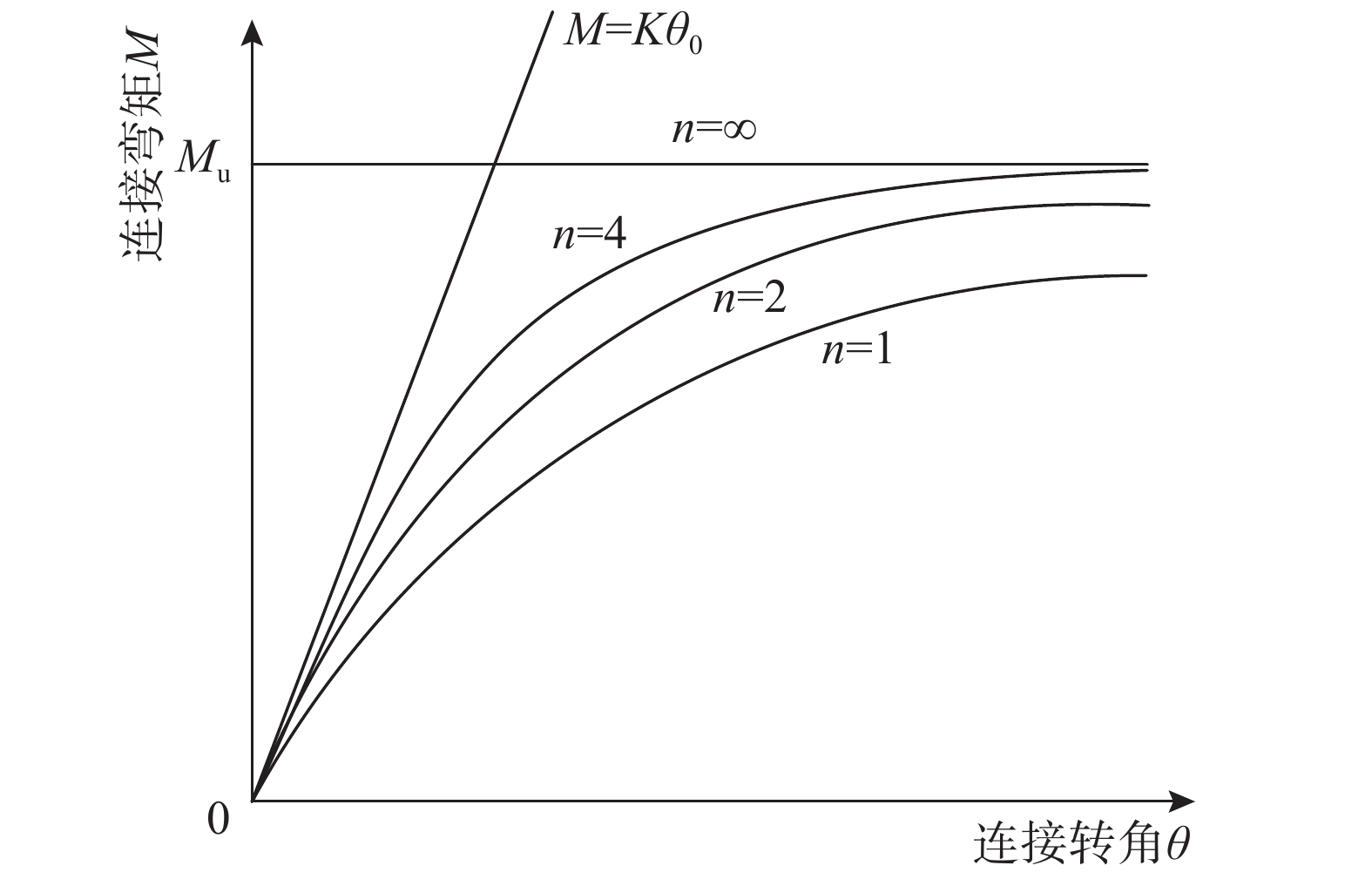

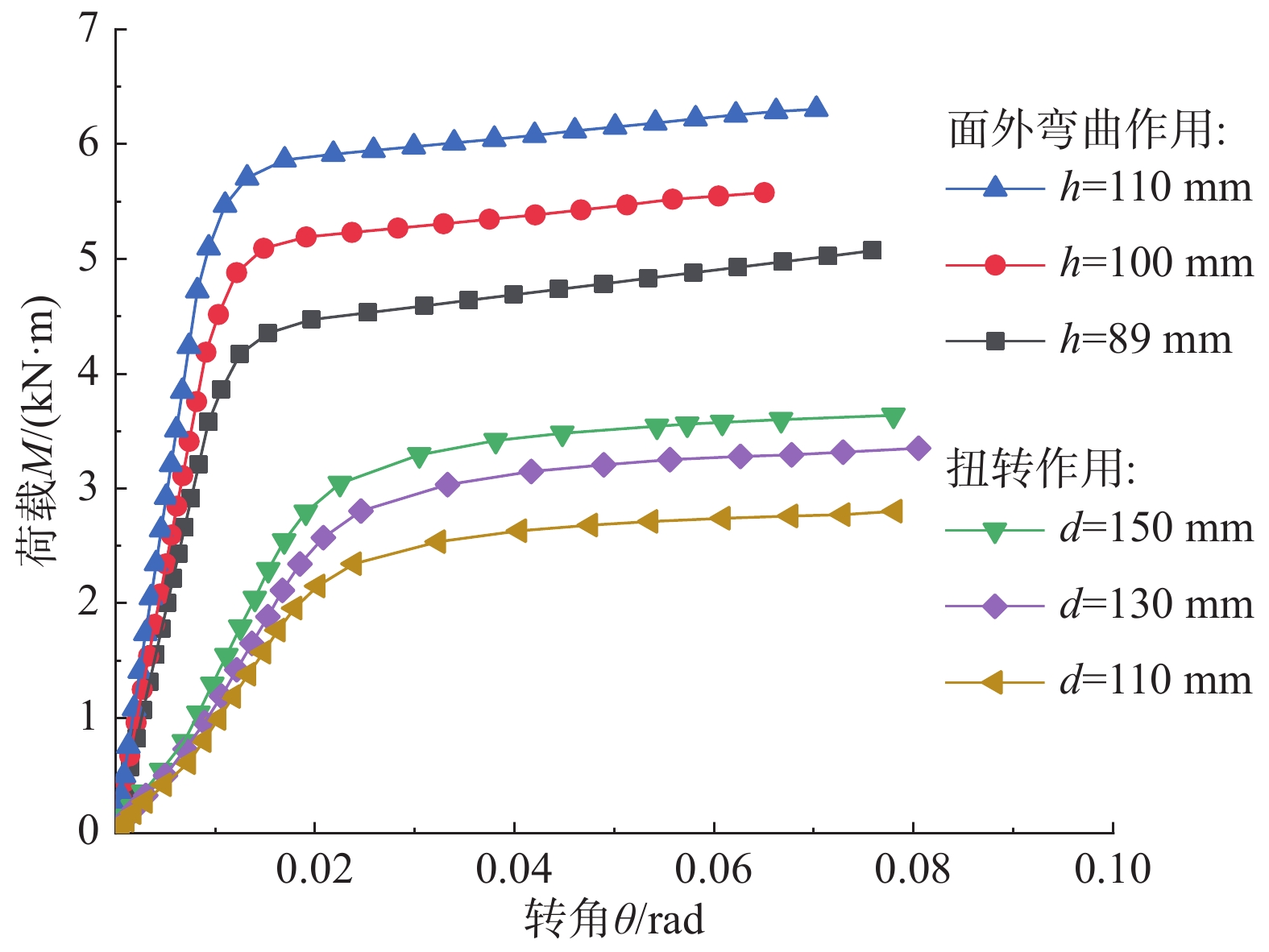

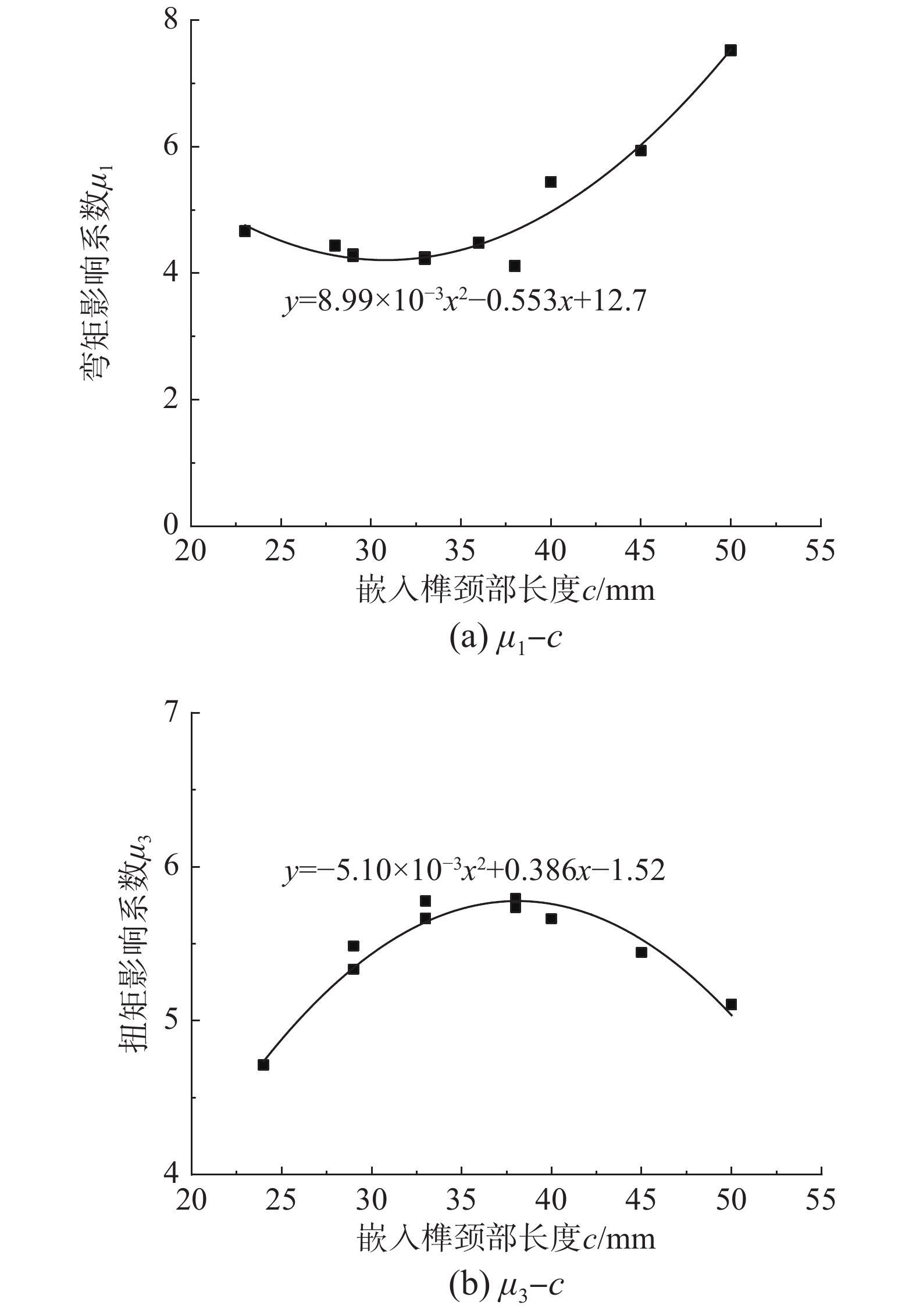

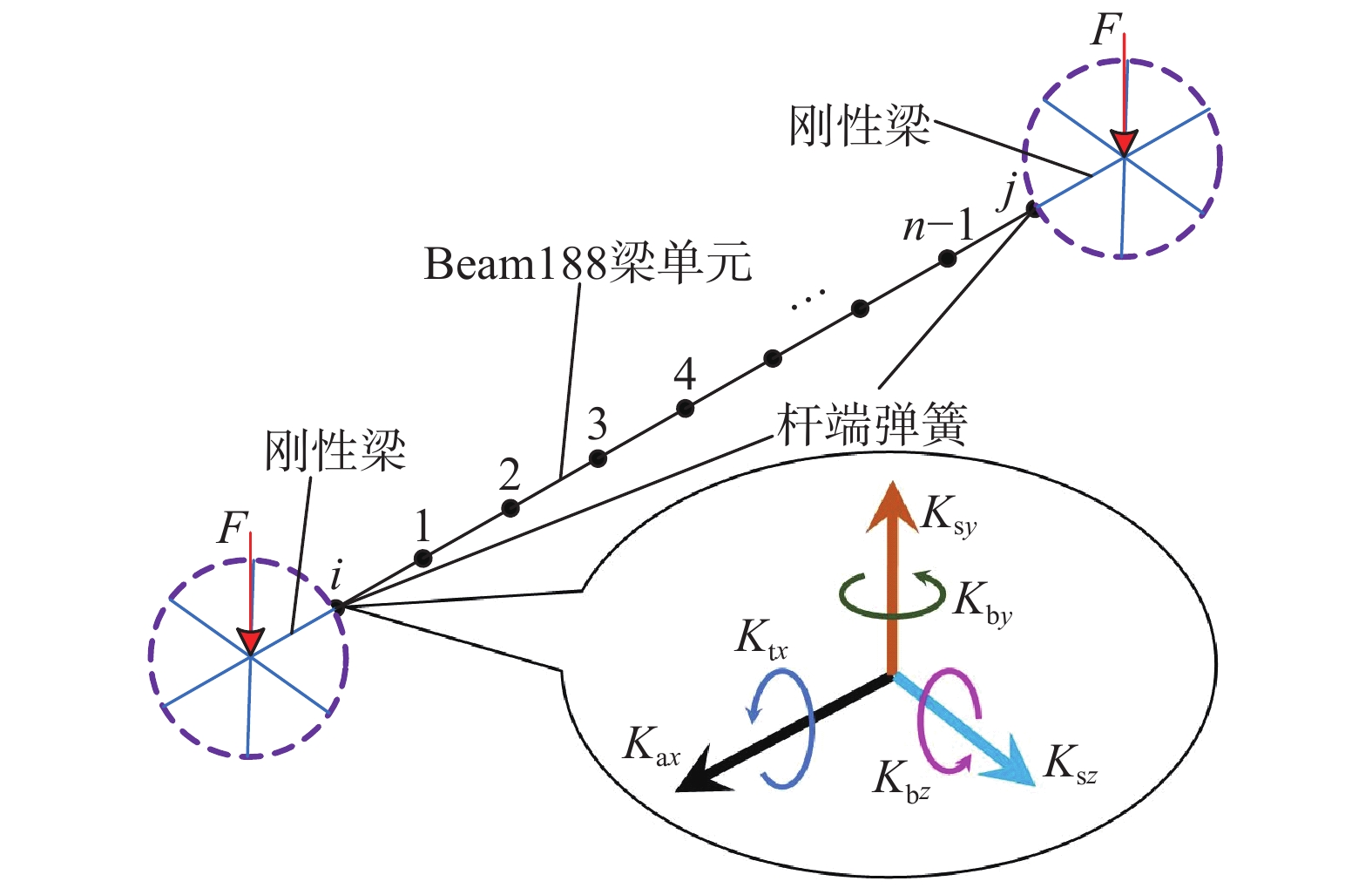

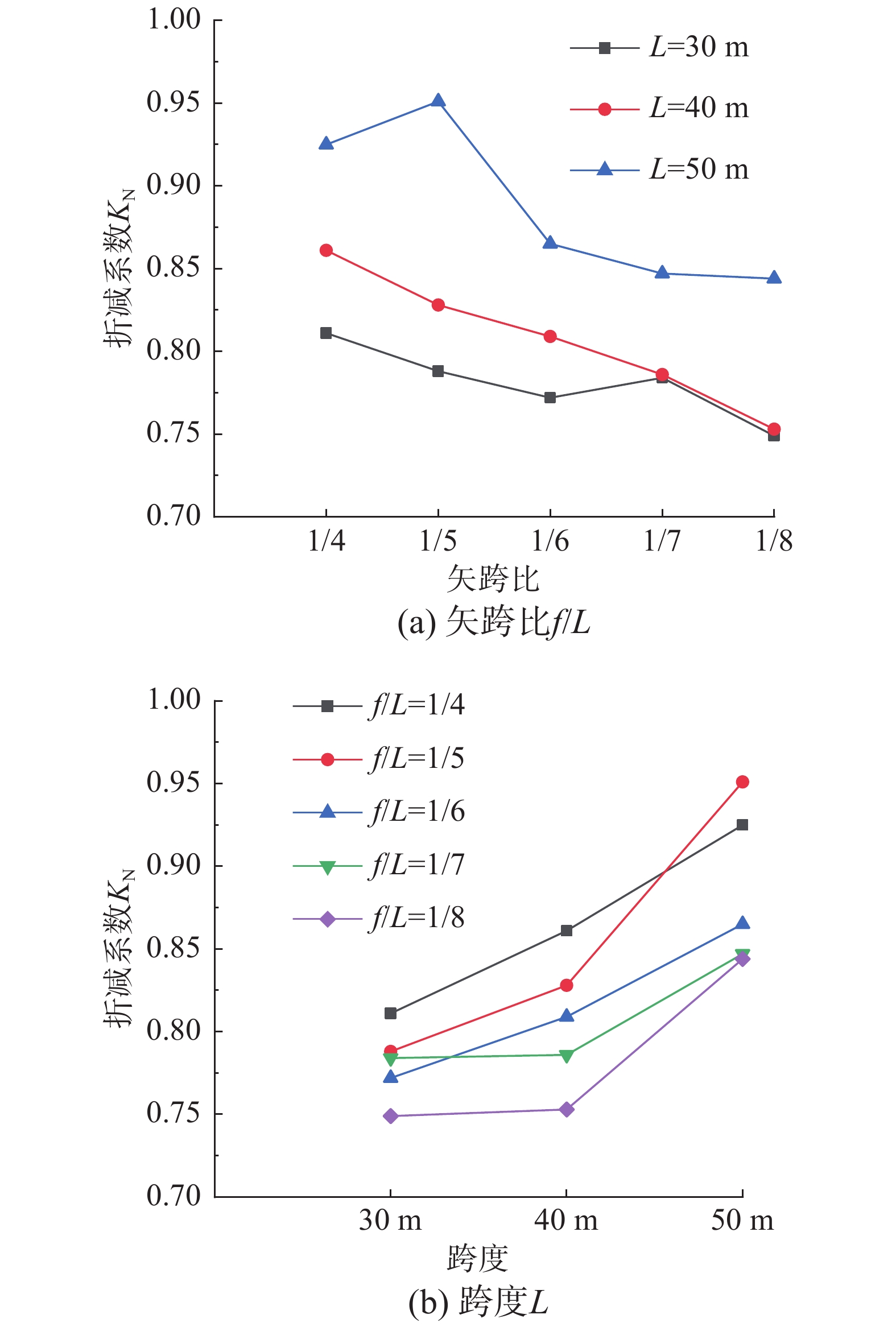

摘要: 嵌入式毂节点是我国自行设计研制出来的一种新型装配式节点,具有施工方便、外形流畅、定位精度高等优点,属于典型的半刚性节点。但目前对此类节点的研究尚不够深入,现有规范尚未涉及此类半刚接单层球面网壳的相关理论计算公式和设计要求。基于此,采用ANSYS软件建立了嵌入式毂节点的精细化模型,基于幂函数模型拟合了节点的弯矩-转角公式,同时,探讨了不同跨度和矢跨比下节点刚度对单层球面网壳稳定承载能力的影响。研究表明:嵌入式毂节点在平面外弯曲时的弯矩-转角曲线以及在扭转作用时的扭矩-转角曲线均与幂函数模型吻合良好;网壳结构承载力对节点弯曲刚度的敏感程度要大于节点轴向刚度,且极限承载力对节点刚度的敏感程度会随着结构跨度或矢跨比的增大均呈现减弱的趋势。Abstract: The hub-shape inlay joint is a new type of assembled joint designed and developed in China, and has the advantages of convenient construction, smooth shape and high positioning accuracy, and it belongs to a typical semi-rigid joint. However, the research on this kind of joints is limited, and existing codes do not contain the relevant theoretical calculation formulas and design requirements for the semi-rigid single-layer spherical reticulated shell. Recognizing the aforementioned issues, a refined model of the hub-shape inlay joint is established by ANSYS package, and the moment-rotation curve of the joint is fitted based on the power function model. Meanwhile, the influence of joint stiffness on ultimate bearing capacity of the semi-rigid shell with different spans and rise-to-span ratios is discussed in detail. The results show that the moment-rotation curves of the hub-shape inlay joints in out-of-plane bending and torsional bending are in good agreement with the power function model. The sensitivity of the ultimate bearing capacity of shell to the bending stiffness of the joints is greater than the axial stiffness of the joints, and the sensitivity of the ultimate bearing capacity to the stiffness of the joints will get weaker with the increase of the span or rise-to-span ratio of the shell.

-

-

表 1 节点的几何尺寸

Table 1 Geometric sizes of the hub-shape inlay joint

毂体

高度

h/mm毂体

直径

d/mm嵌入榫

颈部

长度c/mm嵌入榫

直径

r/mm嵌入榫

颈部

宽度b/mm杆件

外径

da/mm杆件

内径

db/mm杆端嵌入

件总长

Lhp/mm114 150 33 20 13 114 104 192 表 2 不同嵌入式毂节点的尺寸参数

Table 2 Dimension parameters of different joints

节点组号 G48 G60 G89 G114 G133 G140 毂体高度h/mm 48 60 89 114 133 140 毂体直径d/mm 130 130 150 150 180 240 嵌入榫颈部

长度c/mm29 29 33 33 40 50 表 3 节点在平面外弯曲作用下幂函数模型中的形状参数

Table 3 Shape parameters in power function model of nodes under out of plane bending

节点组号 G48 G60 G89 G114 G133 G140 形状参数n1 4.033 4.746 2.261 1.850 1.964 1.844 表 4 节点在扭转作用下幂函数模型中的形状参数

Table 4 Shape parameters in power function model of joints under torsion

节点组号 G48 G60 G89 G114 G133 G140 形状参数n3 4.519 7.389 9.214 8.783 2.893 5.760 表 5 不同节点刚度下网壳的极限承载力

Table 5 Ultimate bearing capacity of reticulated shells with different joint stiffness

网壳类型 极限承载力/(kN/m2) 影响系数KN Shell A 9.61 − Shell B 8.81 0.917 Shell C 7.99 0.831 Shell D 7.24 0.753 表 6 矢跨比和跨度对半刚性网壳极限承载力的影响

Table 6 Influence of rise span ratio and span on ultimate bearing capacity of semi rigid reticulated shells

跨度/m 矢跨比 刚接网壳极限

承载力/(kN/m2)半刚接网壳极

限承载力/(kN/m2)折减系数

KN30 1/4 34.89 28.30 0.811 1/5 28.51 22.48 0.788 1/6 23.81 18.39 0.772 1/7 19.74 15.48 0.784 1/8 17.44 13.06 0.749 40 1/4 18.77 16.17 0.861 1/5 15.26 12.63 0.828 1/6 12.84 10.39 0.809 1/7 11.05 8.69 0.786 1/8 9.61 7.24 0.753 50 1/4 10.85 10.04 0.925 1/5 8.63 8.21 0.951 1/6 7.56 6.54 0.865 1/7 6.59 5.58 0.847 1/8 5.24 4.42 0.844 -

[1] Chung BangYun, Jin HakYi, Eun YoungBahng. Joint Damage Assessment of Framed Structures Using a Neural Networks Technique [J]. Engineering Structures, 2001, 23: 425 − 431. doi: 10.1016/S0141-0296(00)00067-5

[2] Rafiq Hasan, Norimitsu Kishi, Wai-Fah Chen. A new nonlinear connection classification system [J]. Journal of Constructional Steel Research, 1998, 47(1): 119 − 140. doi: 10.1016/S0143-974X(98)80105-3

[3] 李永泉, 何若全. 框架半刚性连接的研究概述[J]. 哈尔滨建筑工程学院学报, 1994, 27(3): 112 − 119. Li Yongquan, He Ruoquan. Summary of research on semi-rigid frame connection [J]. Journal of Harbin Institute of Architectural Engineering, 1994, 27(3): 112 − 119. (in Chinese)

[4] Nanda B K, Behera A K. Study on structural damping of aluminum using multi-layered and Jointed construction [J]. Structural Engineering and Mechanics, 2005, 20(6): 631 − 653. doi: 10.12989/sem.2005.20.6.631

[5] Hiyama Y, Ishikawa K, Kato S, et al. Experiments and analysis of the post-bucking behavious of aluminum alloy double layer spare grids applying ball joints [J]. Structural Engineering and Mechanics, 2005, 9(3): 289 − 304.

[6] 廖俊, 张毅刚. 焊接空心球节点荷载-位移曲线双线性模型研究[J]. 空间结构, 2010, 16(2): 31 − 38. Liao Jun, Zhang Yigang. Research on bilinear model of load displacement curve of welded hollow spherical joints [J]. Space structure, 2010, 16(2): 31 − 38. (in Chinese)

[7] 范峰, 马会环, 马越洋. 半刚性节点网壳结构研究进展及关键问题[J]. 工程力学, 2019, 36(7): 1 − 7, 29. doi: 10.6052/j.issn.1000-4750.2018.06.ST05 Fan Feng, Ma Huihuan, Ma Yueyang. Development and key issues of reticulated shells with semi-rigid joints [J]. Engineering Mechanics, 2019, 36(7): 1 − 7, 29. (in Chinese) doi: 10.6052/j.issn.1000-4750.2018.06.ST05

[8] 郭小农, 朱劭骏, 熊哲, 罗永峰. K6型铝合金板式节点网壳稳定承载力设计方法[J]. 建筑结构学报, 2017, 38(07): 16 − 24. Guo Xiaonong, Zhu Shaojun, Xiong Zhe, Luo Yongfeng. Design method for stability bearing capacity of K6 aluminum alloy plate joint reticulated shell [J]. Journal of Architectural Structure, 2017, 38(07): 16 − 24. (in Chinese)

[9] 朱南海, 李杰明. 基于节点构形度均衡化的单层网壳结构优化设计研究[J]. 工程力学, 2021, 38(6): 113 − 120, 132. doi: 10.6052/j.issn.1000-4750.2020.07.0441 Zhu Nanhai, Li Jieming. Study on the optimization design of single-layer reticulated shell based on the homogenization of nodal well-formedness [J]. Engineering Mechanics, 2021, 38(6): 113 − 120, 132. (in Chinese) doi: 10.6052/j.issn.1000-4750.2020.07.0441

[10] 姜守芳, 李会军, 龙婷婷. 考虑节点偏差、杆件缺陷与偏心的单层三向柱面网壳稳定性研究[J]. 工程力学, 2022, 39(2): 178 − 188. doi: 10.6052/j.issn.1000-4750.2021.01.0005 Jiang Shoufang, Li Huijun, Long Tingting. Stability of single-layer three-way reticulated barrel vaults considering global geometric imperfection, member imperfection and eccentricity [J]. Engineering Mechanics, 2022, 39(2): 178 − 188. (in Chinese) doi: 10.6052/j.issn.1000-4750.2021.01.0005

[11] 赵中伟, 吴刚. 锈蚀焊接空心球节点随机抗压承载力研究[J]. 工程力学, 2021, 38(5): 219 − 228, 238. doi: 10.6052/j.issn.1000-4750.2020.07.0472 Zhao Zhongwei, Wu Gang. Random compression capacity of corroded WHSJS [J]. Engineering Mechanics, 2021, 38(5): 219 − 228, 238. (in Chinese) doi: 10.6052/j.issn.1000-4750.2020.07.0472

[12] 王先铁, 郝际平, 钟炜辉, 丁维. 一种新型网壳结构节点的试验研究与有限元分析[J]. 西安建筑科技大学学报(自然科学版), 2005(3): 316 − 321. Wang Xiantie, Hao Jiping, Zhong Weihui, Ding Wei. Experimental study and finite element analysis of a new type of reticulated shell joint [J]. Journal of Xi'an University of Architecture and Technology (Natural Science Edition), 2005(3): 316 − 321. (in Chinese)

[13] 李云峰. 一种空间网壳结构毂型节点受力性能研究[D]. 张家口: 河北建筑工程学院, 2019. Li Yunfeng. Research on the mechanical behavior of hub joints of a spatial reticulated shell structure [D]. Zhangjiakou: Hebei Institute of Architecture and Engineering, 2019. (in Chinese)

[14] Li Huijun, Taniguchi Yoshiya. Effect of joint stiffness and size on stability of three-way single-layer cylindrical reticular shell [J]. International Journal of Space Structures, 2020, 35(3): 90 − 107. doi: 10.1177/0956059920931019

[15] Ma Yueyang, Huihuan Ma, Zhiwei Yu, et al. Experimental and numerical study on the cyclic performance of the gear-bolt semi-rigid joint under uniaxial bending for free-form lattice shells [J]. Journal of Constructional Steel Research, 2018, 149: 257 − 268. doi: 10.1016/j.jcsr.2018.07.012

[16] Ma Huihuan, Ren Shan, Fan Feng. Parametric study and analytical characterization of the bolt–column (BC) joint for single-layer reticulated structures [J]. Engineering Structures, 2016, 123: 108 − 123. doi: 10.1016/j.engstruct.2016.05.037

[17] 叶继红, 陆明飞. 单层空间网格结构刚性节点优化设计方法研究[J]. 工程力学, 2020, 37(2): 81 − 89, 144. doi: 10.6052/j.issn.1000-4750.2019.01.0092 Ye Jihong, Lu Mingfei. Design optimization method of rigid nodes in single-layer gridshells [J]. Engineering Mechanics, 2020, 37(2): 81 − 89, 144. (in Chinese) doi: 10.6052/j.issn.1000-4750.2019.01.0092

[18] JG/T 136−2016, 单层网壳嵌入式毂节点[S]. 北京: 中国建筑工业出版社, 2016. JG/T 136−2016, single layer reticulated shell embedded hub node [S]. Beijing: China Construction Industry Press, 2016. (in Chinese)

[19] 姜栋. 单层网壳节点半刚性及其对结构整体稳定性影响的研究[D]. 杭州: 浙江大学, 2016. Jiang Dong. Research on semi-rigid joints of single-layer reticulated shells and their influence on overall stability of structures [D]. Hangzhou: Zhejiang University, 2016. (in Chinese)

[20] 马越洋. 新型齿式半刚性节点静动力性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2016. Ma Yueyang. Research on static and dynamic performance of new type semi-rigid joints with teeth [D]. Harbin: Harbin Institute of technology, 2016. (in Chinese)

[21] Kishi N, Chen W F. Moment-rotation relations of semi-rigid connections with angles [J]. Journal of Structural Engineering, 1990, 116(7): 1813 − 1834. doi: 10.1061/(ASCE)0733-9445(1990)116:7(1813)

[22] 郑靖潇. 空心毂节点铝合金单层网壳稳定性与抗连续倒塌性能研究[D]. 天津: 天津大学, 2018. Zheng Jingxiao. Study on stability and progressive collapse resistance of aluminum alloy single-layer reticulated shells with hollow hub joints [D]. Tianjin: Tianjin University, 2018. (in Chinese)

[23] Li Huijun, Taniguchi Yoshiya. Coupling effect of nodal deviation and member imperfection on load-carrying capacity of single-layer reticulated shell [J]. International Journal of Steel Structures, 2020, 20(3): 919 − 930. doi: 10.1007/s13296-020-00332-6

-

期刊类型引用(9)

1. 刘旭宏,祁皑,罗才松,黄凯. 基于双重壳模型的钢筋黏结滑移有限元模拟. 工程抗震与加固改造. 2022(03): 23-29 .  百度学术

百度学术

2. 赵发军,李建. 基于ABAQUS的复合箍筋约束轻骨料混凝土柱偏压力学性能研究. 中国测试. 2022(09): 171-176+184 .  百度学术

百度学术

3. 陈宇良,朱玲,吉云鹏,吴辉琴,叶培欢. 三轴受压粉煤灰陶粒轻骨料混凝土力学性能试验. 复合材料学报. 2022(10): 4801-4812 .  百度学术

百度学术

4. 万宇通,郑文忠,王英. 网格箍筋约束混凝土柱轴压受力性能试验研究. 工程力学. 2022(11): 166-176 .  本站查看

本站查看

5. 牛建刚,许文明,梁剑. 受压区局部约束塑钢纤维轻骨料混凝土梁的抗弯性能. 材料导报. 2021(08): 8056-8063 .  百度学术

百度学术

6. 李磊,王卓涵,张艺欣,郑山锁. 混凝土结构中考虑滑移效应的钢筋本构模型研究. 工程力学. 2020(03): 88-97 .  本站查看

本站查看

7. 邓宗才,姚军锁. 高强钢筋约束超高性能混凝土柱轴心受压本构模型研究. 工程力学. 2020(05): 120-128 .  本站查看

本站查看

8. 赵恩亮. 不同侧向应力作用下轻骨料混凝土力学性能研究. 新型建筑材料. 2020(05): 17-21 .  百度学术

百度学术

9. 周天华,余吉鹏,李亚鹏,张钰. 单轴对称十字型钢混凝土短柱轴压性能试验研究. 工程力学. 2020(12): 157-170 .  本站查看

本站查看

其他类型引用(14)

下载:

下载: