AUTOMATION EXTRACTION AND QUANTIFICATION OF SHEAR CRACKS IN REINFORCED CONCRETE BEAMS BASED ON DIC TECHNOLOGY

-

摘要:

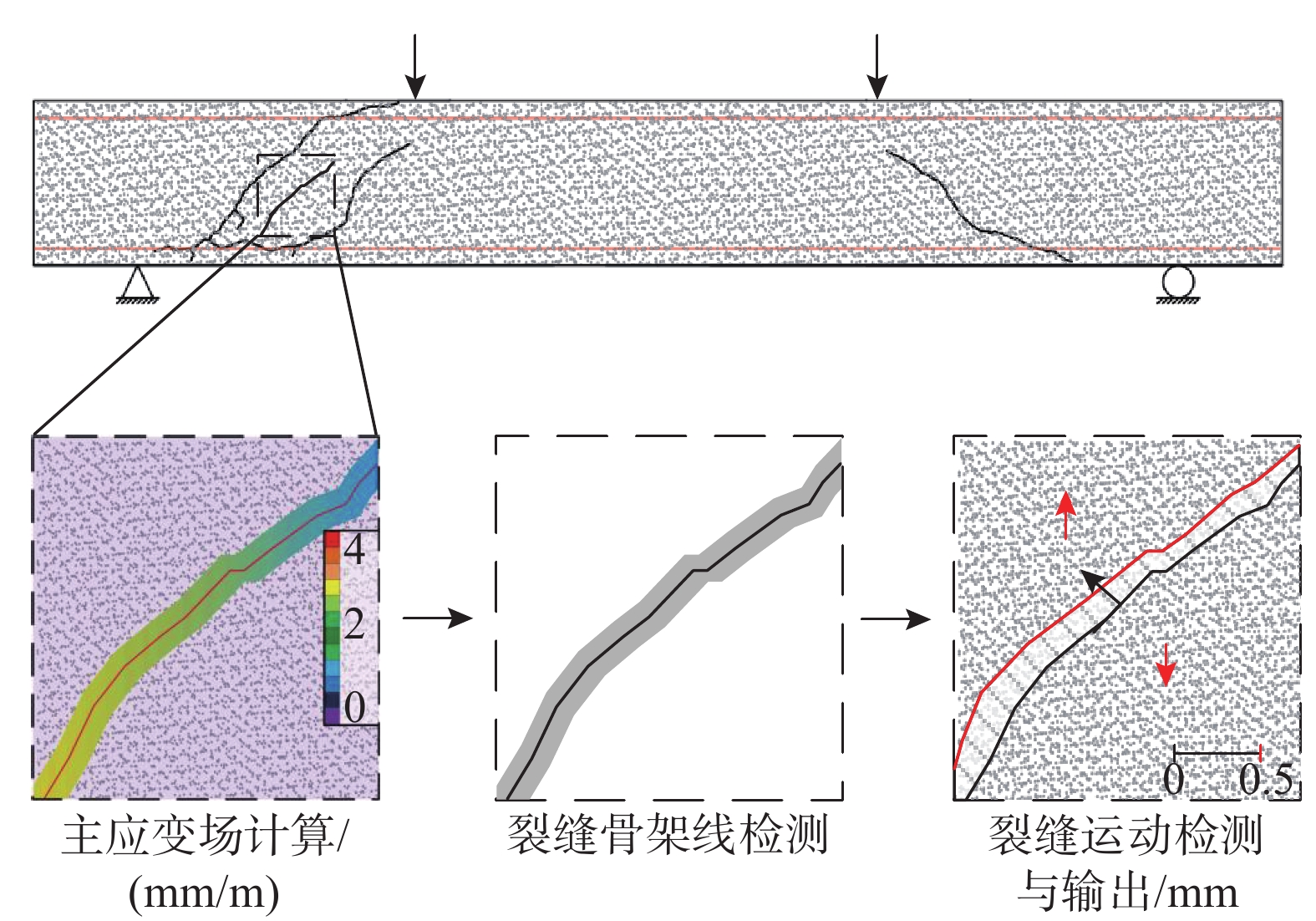

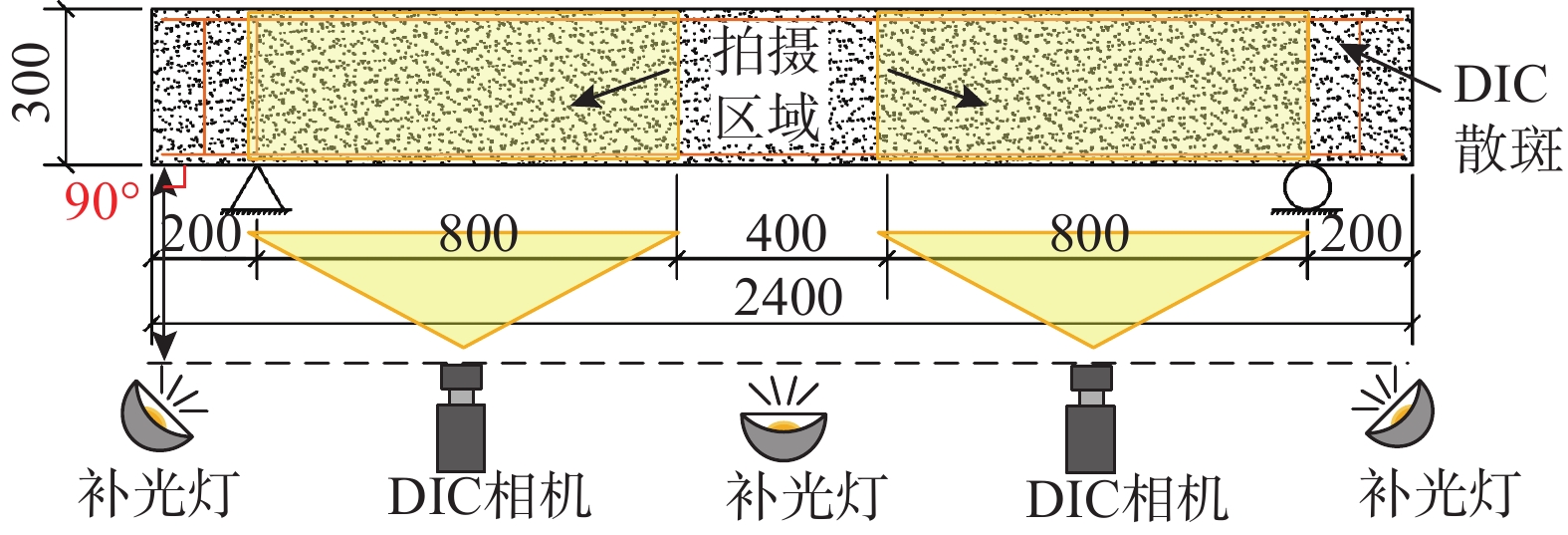

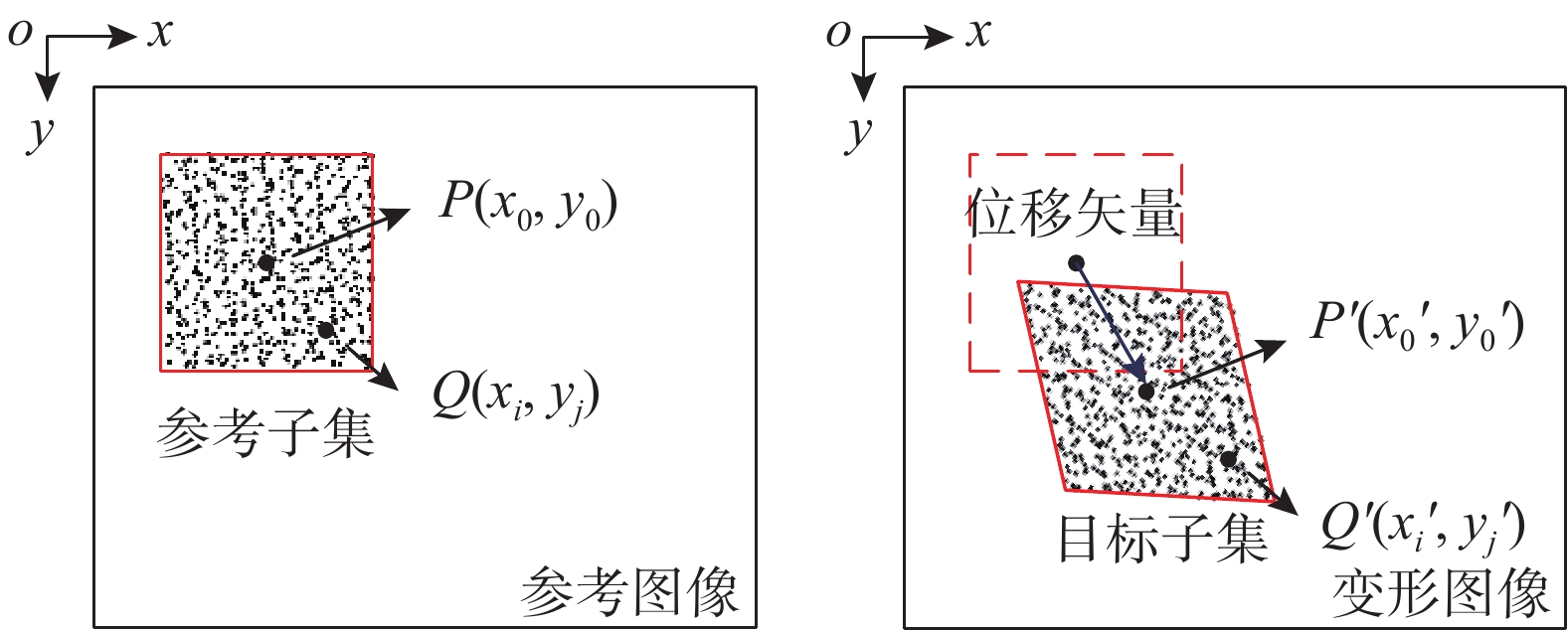

针对钢筋混凝土梁实验中剪切斜裂缝的自动化定位、全域范围内各方向宽度量化及扩展追踪问题,该文提出一种基于数字图像相关技术(DIC)的裂缝自动提取与宽度量化的计算方法。由DIC计算得出的水平、竖直、剪切应变场来计算试件表面的主拉伸应变场,并将试件表面主应变大于某一阈值的部分视为开裂。对开裂部分进行形态学操作,提取出裂缝骨架线。在骨架线两侧定义裂缝运动参考点,根据参考点的运动来计算裂缝的发展规律。该计算方法实现了混凝土梁加载过程中任意方向上裂缝自动化检测及高精度量化,并且能够处理试件局部旋转的问题,充分了利用DIC测量技术的潜力。通过实验室内四组钢筋混凝土梁剪切实验验证该方法的有效性与精度。结果表明:该方法能够在多加载阶段实时追踪全域范围内各方向的裂缝开展并量化。

Abstract:To address the problems of automatic localization, width quantification in all directions and extended tracking of shear diagonal cracks in reinforced concrete beam experiments, this paper proposes a computational method for automatic crack extraction and width quantification based on digital image correlation (DIC) technology. The horizontal, vertical and shear strain fields calculated by DIC are used to calculate the principal tensile strain fields on specimen surface, and the part of the specimen surface where the principal strain is greater than a certain threshold value is considered as cracked. Morphological operations are performed on the cracked portion to extract the crack skeleton line. Reference points for crack movement are defined on both sides of the skeleton line, and the crack development pattern is calculated based on the movement of the reference points. The calculation method achieves automated detection and high accuracy quantification of cracks in any direction during the loading of concrete beams, and is able to handle local rotation of the specimen, leveraging the full potential of DIC measurement technique. The validity and accuracy of the method are verified through four sets of laboratory shear tests of reinforced concrete beams. The results show that the method is capable of tracking and quantifying the crack development in all directions over the full range in real time during multiple loading stages.

-

-

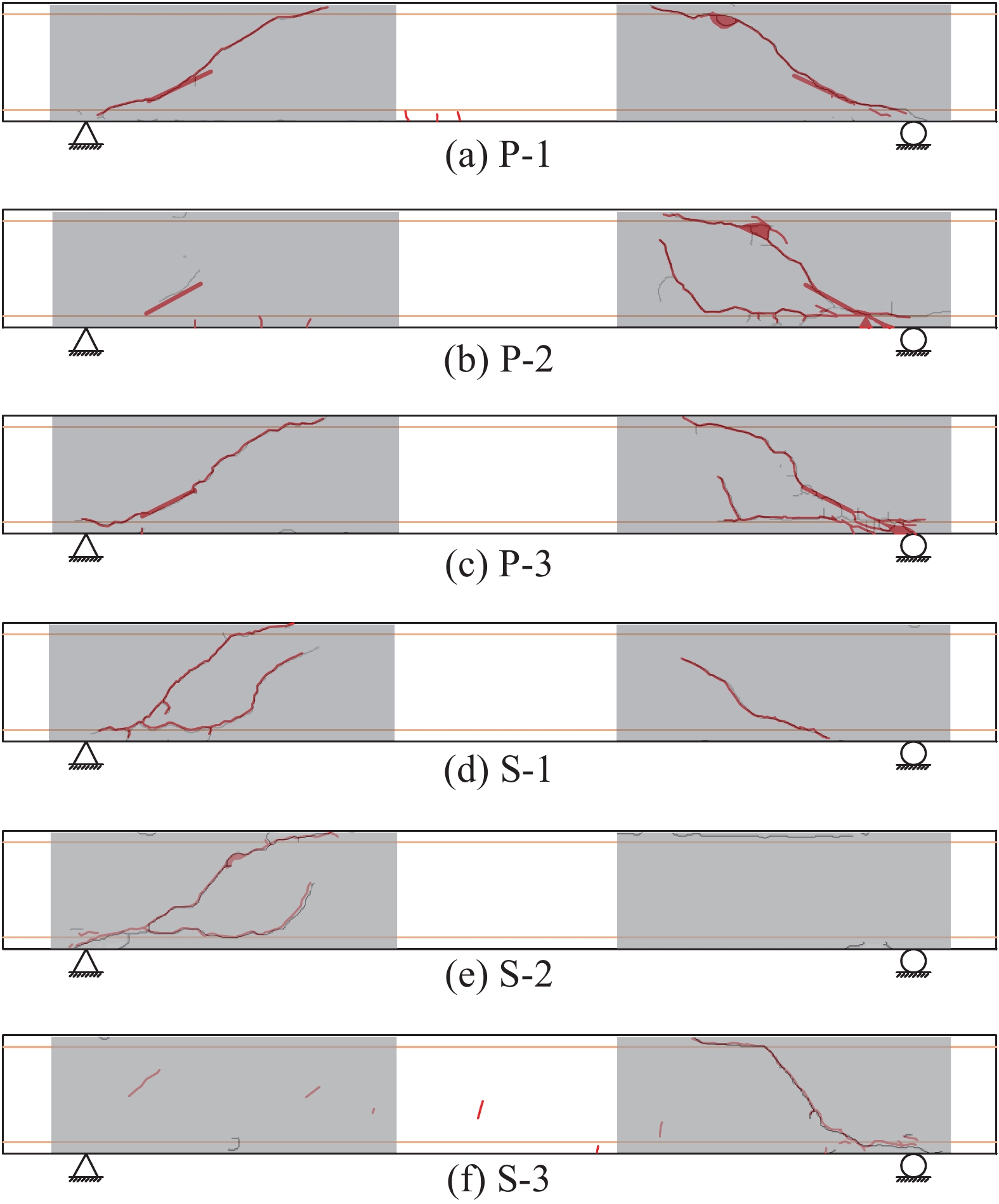

图 12 裂缝自动提取量化方法提取与手工记录裂缝破坏模式对比图(阴影部分为相机拍摄到的ROI区域,黑色线条为裂缝自动提取量化方法得到的裂缝模式图,红色线条为手工绘制的裂缝模式图)

Figure 12. Comparison of the crack damage pattern extracted by the automatic crack extraction quantification method and the manually recorded crack damage pattern (the shaded area is the ROI area captured by the camera; the black line is the crack pattern map obtained by the automatic crack extraction quantification method; the red line is the manually drawn crack pattern map)

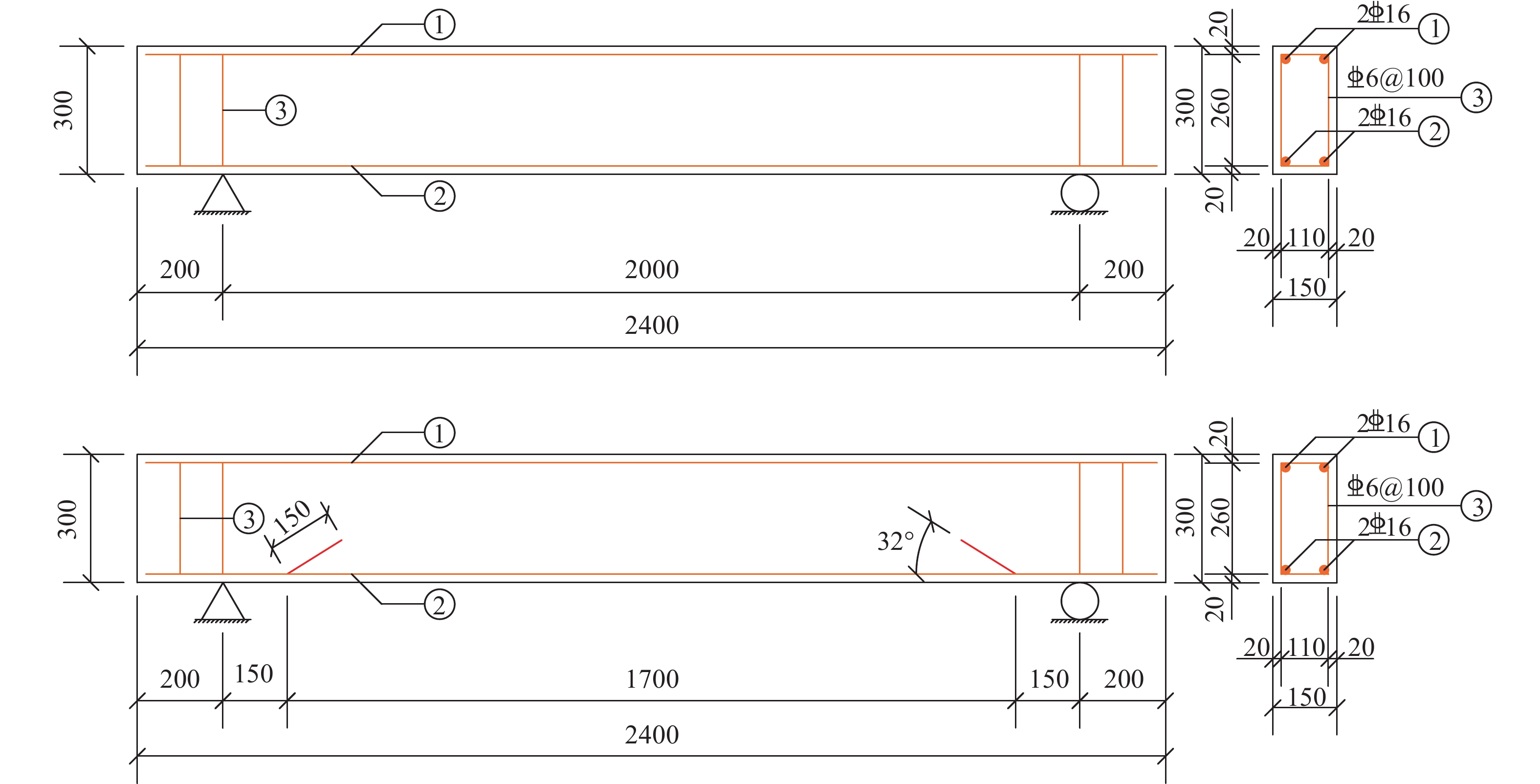

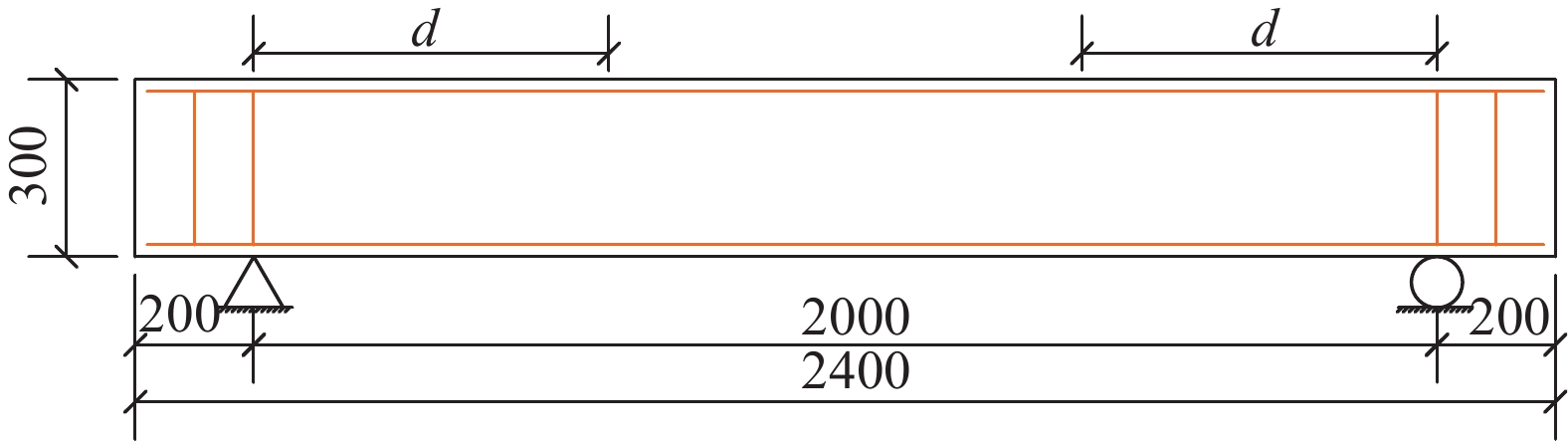

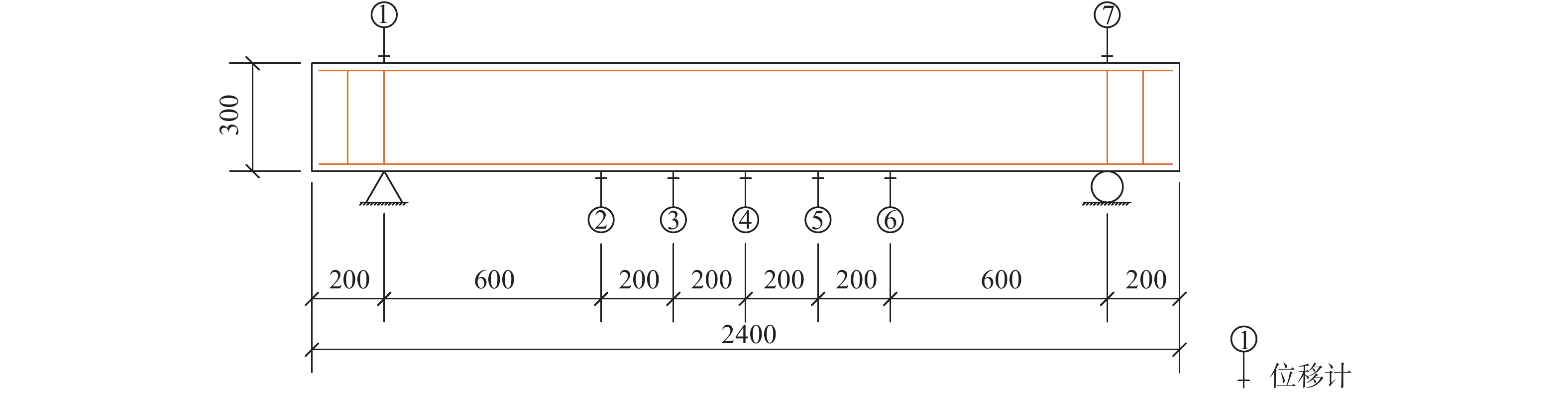

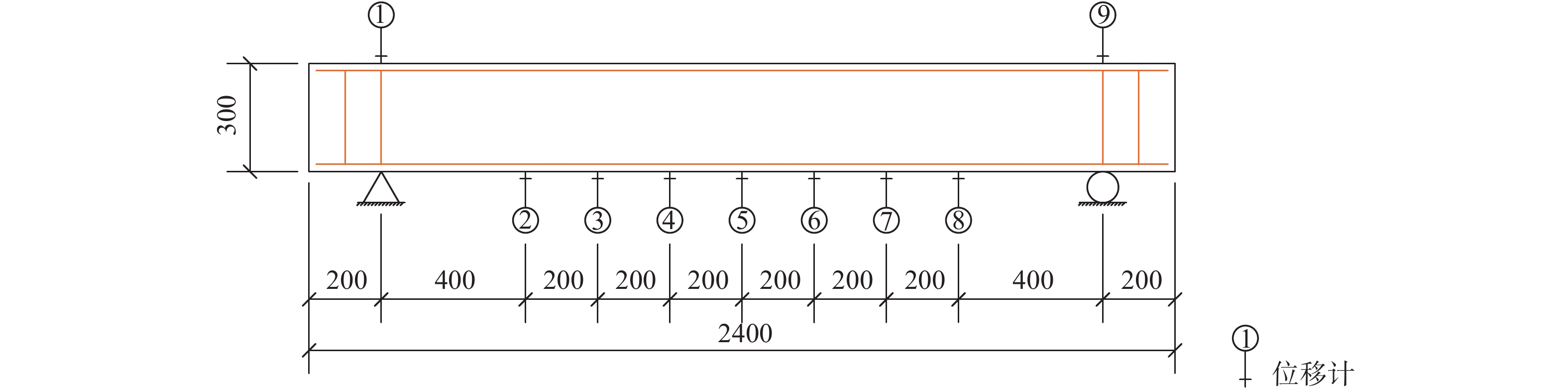

表 1 荷载作用位置

Table 1 Location of load

加载制度\组别 对照组(C) 大剪跨比(L) 小剪跨比(S) 预制裂缝(P) 制造初始裂缝 − d=800 d=400 − 正式加载 d=600 d=600 d=800 d=600 注:d为加载位置至支座的距离。 表 2 LVDT与DIC挠度对比表格

Table 2 Deflection comparison of LVDT and DIC

构件 加载组别 荷载水平/

kN测量

点位挠度-

LVDT挠度-

DIC误差/

(%)L-2 制造初始裂缝(Nmax=110.6 kN) 91.5 2 2.44 2.45 0.4 正式加载(Nmax=112.7 kN) 112.3 2 4.78 4.80 0.4 S-1 制造初始裂缝(Nmax=97.5 kN) 96.0 3 2.03 2.16 6.0 4 2.18 2.27 4.0 正式加载(Nmax=110.9 kN) 95.0 3 2.66 2.72 2.0 4 3.06 3.04 0.6 S-2 正式加载(Nmax=106.0 kN) 105.6 7 2.06 2.06 0.0 8 1.60 1.65 3.0 S-3 制造初始裂缝(Nmax=107.0 kN) 82.2 3 1.28 1.29 0.7 4 1.46 1.42 2.0 正式加载(Nmax=118.0 kN) 117.8 3 2.52 2.55 1.0 4 2.79 2.82 1.0 P-2 正式加载(Nmax=84.2 kN) 84.1 5 4.44 4.58 3.0 P-3 正式加载(Nmax=101.5 kN) 101.2 5 4.93 4.86 1.0 表 3 裂缝自动提取量化及手工记录裂缝宽度对比表格

Table 3 Comparison between automatic crack extraction quantification and manual recording of crack widths

组别 加载阶段 荷载水平 北侧(手工记录结果/裂缝自动提取量化方法结果) 南侧(手工记录结果/裂缝自动提取量化方法结果) L-1 制造初始裂缝(Nmax=110.6 kN) 0.87 Nmax 0.10 mm/0.06 mm −/− 0.93 Nmax 0.10 mm、0.08 mm/0.10 mm、0.09 mm −/− 0.96 Nmax 0.10 mm、0.10 mm/0.10 mm、0.12 mm −/− L-2 制造初始裂缝(Nmax=92.8 kN) 0.86 Nmax 0.15 mm/0.12 mm − Nmax 0.20 mm/0.17 mm − 正式加载(Nmax=112.7 kN) 0.80 Nmax 0.20 mm/0.15 mm − 0.86 Nmax 0.40 mm/0.33 mm − 0.90 Nmax 2.00 mm/1.80 mm − S-1 制造初始裂缝(Nmax=97.5 kN) 0.72 Nmax − − 0.98 Nmax − 0.05 mm/0.05 mm Nmax − 0.20 mm/0.24 mm 正式加载(Nmax=110.9 kN) 0.54 Nmax −/0.01 mm 0.15 mm/0.15 mm 0.84 Nmax 0.15 mm/0.20 mm 0.80 mm/0.85 mm 0.85 Nmax 0.17 mm/0.25 mm 1.35 mm/1.40 mm S-2 制造初始裂缝(Nmax=109.6 kN) 0.89 Nmax − 0.1 mm/0.09 mm Nmax − 0.15 mm/0.12 mm 正式加载(Nmax=106.0 kN) 0.75 Nmax − − 0.92 Nmax − − 0.98 Nmax 0.05 mm/0.06 mm 1.90 mm/2.00 mm S-3 制造初始裂缝(Nmax=107.0 kN) 0.91 Nmax 0.09 mm/0.12 mm − 0.96 Nmax 0.10 mm/0.14 mm − 正式加载(Nmax=118.0 kN) 0.59 Nmax 0.13 mm/0.12 mm − 0.89 Nmax 0.20 mm/0.18 mm − 0.95 Nmax 0.35 mm/0.30 mm − P-1 正式加载(Nmax=103.4 kN) 0.59 Nmax 0.15 mm/0.11 mm − 0.80 Nmax 0.16 mm/0.12 mm 0.20 mm/0.21 mm 0.87 Nmax 0.20 mm/0.17 mm 0.56 mm/0.60 mm P-2 正式加载(Nmax=84.2 kN) 0.85 Nmax 0.20 mm/0.18 mm − 0.91 Nmax 0.30 mm/0.26 mm − 0.96 Nmax 0.50 mm/0.47 mm − P-3 正式加载(Nmax=101.5 kN) 0.69 Nmax − 0.40 mm/0.33 mm 0.73 Nmax − 1.20 mm/1.15 mm 0.79 Nmax − 1.70 mm/1.80 mm 注:“−”为未录到或没有检测到裂缝;“0.1 mm、0.08 mm”为检测到两条裂缝,宽度分别为0.1 mm和0.08 mm。 -

[1] RUOCCI G, ROSPARS C, MOREAU G, et al. Digital image correlation and noise-filtering approach for the cracking assessment of massive reinforced concrete structures [J]. Strain, 2016, 52(6): 503 − 521. doi: 10.1111/str.12192

[2] LIN J P, LIN L Q, PENG Z X, et al. Cracking performance in the Hogging-Moment regions of natural curing steel-UHPC and steel-UHTCC continuous composite beams [J]. Journal of Bridge Engineering, 2022, 27(2): 04021106. doi: 10.1061/(ASCE)BE.1943-5592.0001820

[3] QI J N, MA Z J, WANG J Q, et al. Post-cracking shear strength and deformability of HSS-UHPFRC beams [J]. Structural Concrete, 2016, 17(6): 1033 − 1046. doi: 10.1002/suco.201500191

[4] ZHANG W, ZHENG Q F, ASHOUR A, et al. Self-healing cement concrete composites for resilient infrastructures: A review [J]. Composites Part B: Engineering, 2020, 189: 107892. doi: 10.1016/j.compositesb.2020.107892

[5] 金浏, 张江兴, 李冬, 等. CFRP布加固方案对RC梁剪切性能及尺寸效应影响分析[J]. 工程力学, 2022, 39(12): 31 − 40. doi: 10.6052/j.issn.1000-4750.2021.07.0558 JIN Liu, ZHANG Jiangxing, LI Dong, et al. Analysis of the influence of CFRP sheets reinforcement scheme on shear performance and size effect of RC beams [J]. Engineering Mechanics, 2022, 39(12): 31 − 40. (in Chinese) doi: 10.6052/j.issn.1000-4750.2021.07.0558

[6] 刘宇飞, 樊健生, 聂建国, 等. 结构表面裂缝数字图像法识别研究综述与前景展望[J]. 土木工程学报, 2021, 54(6): 79 − 98. LIU Yufei, FAN Jiansheng, NIE Jianguo, et al. Review and prospect of digital-image-based crack detection of structure surface [J]. China Civil Engineering Journal, 2021, 54(6): 79 − 98. (in Chinese)

[7] 朱志辉, 冯乾朔, 肖权清, 等. 基于DIC技术和无网格法的裂尖应变场分析方法[J]. 土木工程学报, 2021, 54(6): 99 − 109. ZHU Zhihui, FENG Qianshuo, XIAO Quanqing, et al. An analysis method for strain field of crack tip based on DIC technology and meshless method [J]. China Civil Engineering Journal, 2021, 54(6): 99 − 109. (in Chinese)

[8] 卿龙邦, 曹国瑞, 管俊峰. 基于DIC方法的混凝土允许损伤尺度试验研究[J]. 工程力学, 2019, 36(10): 115 − 121. doi: 10.6052/j.issn.1000-4750.2018.09.0500 QING Longbang, CAO Guorui, GUAN Junfeng. Experimental investigation of the concrete permissible damage scale based on the digital image correlation method [J]. Engineering Mechanics, 2019, 36(10): 115 − 121. (in Chinese) doi: 10.6052/j.issn.1000-4750.2018.09.0500

[9] 晏班夫, 李得睿, 徐观亚, 等. 基于快速DIC与正则化平滑技术的结构形变测试[J]. 中国公路学报, 2020, 33(9): 193 − 205. doi: 10.3969/j.issn.1001-7372.2020.09.019 YAN Banfu, LI Derui, XU Guanya, et al. Structural deformation test based on fast digital image correlation and regularization smoothing techniques [J]. China Journal of Highway and Transport, 2020, 33(9): 193 − 205. (in Chinese) doi: 10.3969/j.issn.1001-7372.2020.09.019

[10] 刘聪, 陈振宁, 何小元. 3D-DIC在土木结构力学性能试验研究中的应用[J]. 东南大学学报(自然科学版), 2014, 44(2): 339 − 344. doi: 10.3969/j.issn.1001-0505.2014.02.020 LIU Cong, CHEN Zhenning, HE Xiaoyuan. Application of 3D-DIC in experimental study on mechanical properties of civil structures [J]. Journal of Southeast University (Natural Science Edition), 2014, 44(2): 339 − 344. (in Chinese) doi: 10.3969/j.issn.1001-0505.2014.02.020

[11] HOULT R, DE ALMEIDA J P. From experimental strain and crack distributions to plastic hinge lengths of RC walls with SMA rebars [J]. Engineering Structures, 2022, 268: 114731. doi: 10.1016/j.engstruct.2022.114731

[12] HELM J D. Digital image correlation for specimens with multiple growing cracks [J]. Experimental Mechanics, 2008, 48(6): 753 − 762. doi: 10.1007/s11340-007-9120-2

[13] AL-SALIH H, JUNO M, COLLINS W, et al. Application of a digital image correlation bridge inspection methodology on geometrically complex bifurcated distortion‐induced fatigue cracking [J]. Fatigue & Fracture of Engineering Materials & Structures, 2021, 44(11): 3186 − 3201.

[14] GHORBANI R, MATTA F, SUTTON M A. Full-field deformation measurement and crack mapping on confined masonry walls using digital image correlation [J]. Experimental Mechanics, 2015, 55(1): 227 − 243. doi: 10.1007/s11340-014-9906-y

[15] CHRISTENSEN C O, SCHMIDT J W, HALDING P S, et al. Digital image correlation for evaluation of cracks in reinforced concrete bridge slabs [J]. Infrastructures, 2021, 6(7): 99 − 123. doi: 10.3390/infrastructures6070099

[16] 廖健, 章红梅, 陈杨. 基于数字图像相关法(DIC)的剪力墙破坏过程分析[J]. 结构工程师, 2019, 35(3): 83 − 90. doi: 10.3969/j.issn.1005-0159.2019.03.012 LIAO Jian, ZHANG Hongmei, CHEN Yang. Analysis of the shear wall failure process based on DIC method [J]. Structural Engineers, 2019, 35(3): 83 − 90. (in Chinese) doi: 10.3969/j.issn.1005-0159.2019.03.012

[17] POHORYLES D A, MELO J, ROSSETTO T, et al. Use of DIC and AE for monitoring effective strain and debonding in FRP and FRCM-retrofitted RC beams [J]. Journal of Composites for Construction, 2017, 21(1): 04016057. doi: 10.1061/(ASCE)CC.1943-5614.0000715

[18] FUNARI M F, VERRE S. The effectiveness of the DIC as a measurement system in SRG shear strengthened reinforced concrete beams [J]. Crystals, 2021, 11(3): 265 − 276. doi: 10.3390/cryst11030265

[19] ALAM S Y, LOUKILI A, GRONDIN F, et al. Use of the digital image correlation and acoustic emission technique to study the effect of structural size on cracking of reinforced concrete [J]. Engineering Fracture Mechanics, 2015, 143: 17 − 31. doi: 10.1016/j.engfracmech.2015.06.038

[20] RUOCCI G, ROSPARS C, BISCH P, et al. Cracks distance and width in reinforced concrete membranes: experimental results from cyclic loading histories [C]// 15th World Conference on Earthquake Engineering, Lisbon, Portugal, 2012, 30: 23816 − 23825.

[21] 谷柳凝, 宫文然, 邵新星, 等. 基于主应变场的混凝土全表面开裂特征实时测量与分析[J]. 力学学报, 2021, 53(7): 1962 − 1970. doi: 10.6052/0459-1879-21-107 GU Liuning, GONG Wenran, SHAO Xinxing, et al. Real time measurement and analysis of full surface cracking characteristics of concrete based on principal strain field [J]. Chinese Journal of Theoretical and Applied Mechanics, 2021, 53(7): 1962 − 1970. (in Chinese) doi: 10.6052/0459-1879-21-107

[22] GEHRI N, MATA-FALCÓN J, KAUFMANN W. Automated crack detection and measurement based on digital image correlation [J]. Construction and Building Materials, 2020, 256: 119383. doi: 10.1016/j.conbuildmat.2020.119383

[23] GEHRI N, MATA-FALCÓN J, KAUFMANN W. Refined extraction of crack characteristics in large-scale concrete experiments based on digital image correlation [J]. Engineering Structures, 2022, 251: 113486. doi: 10.1016/j.engstruct.2021.113486

[24] GU L N, SHAO X X. Theoretical analysis of crack propagation measurement for brittle materials based on virtual principal strain field [J]. Acta Mechanica Solida Sinica, 2022, 35(5): 842 − 850. doi: 10.1007/s10338-022-00323-6

[25] SHIH M H, SUNG W P. Application of digital image correlation method for analysing crack variation of reinforced concrete beams [J]. Sadhana, 2013, 38(4): 723 − 741. doi: 10.1007/s12046-013-0141-5

[26] 王鹏鹏, 郭晓霞, 桑勇, 等. 基于数字图像相关技术的砂土全场变形测量及其DEM数值模拟[J]. 工程力学, 2020, 37(1): 239 − 247. doi: 10.6052/j.issn.1000-4750.2019.02.0050 WANG Pengpeng, GUO Xiaoxia, SANG Yong, et al. Full-field deformation measurement of sand using the digital image correlation technique and numerical simulation using the discrete element method [J]. Engineering Mechanics, 2020, 37(1): 239 − 247. (in Chinese) doi: 10.6052/j.issn.1000-4750.2019.02.0050

[27] 白鹏翔, 朱飞鹏, 雷冬. 基于数字图像相关技术的混凝土裂纹探测[J]. 混凝土, 2020(12): 138 − 141, 146. doi: 10.3969/j.issn.1002-3550.2020.12.030 BAI Pengxiang, ZHU Feipeng, LEI Dong. Concrete micro crack detection based on digital image correlation [J]. Concrete, 2020(12): 138 − 141, 146. (in Chinese) doi: 10.3969/j.issn.1002-3550.2020.12.030

[28] 赵宪忠, 李秋云. 土木工程结构试验量测技术研究进展与现状[J]. 西安建筑科技大学学报(自然科学版), 2017, 49(1): 48 − 55. ZHAO Xianzhong, LI Qiuyun. A review on measurement technology for structural testing in civil engineering [J]. Journal of Xi’an University of Architecture & Technology (Natural Science Edition), 2017, 49(1): 48 − 55. (in Chinese)

[29] 李得睿, 周焕新, 程斌. 基于二阶链式子区的金属拉伸试验DIC辅助测试方法[J]. 工程力学, 2024, 41(4): 237 − 246. doi: 10.6052/j.issn.1000-4750.2022.04.0374 LI Derui, ZHOU Huanxin, CHENG Bin. DIC-Aided metal tensile test technology using chain-like second order sub-regions [J]. Engineering Mechanics, 2024, 41(4): 237 − 246. (in Chinese) doi: 10.6052/j.issn.1000-4750.2022.04.0374

[30] 邢国华, 黄娇, 罗小宝, 等. 预应力铝合金筋嵌入式补强钢筋混凝土梁裂缝分析与计算[J]. 工程力学, 2022, 39(3): 171 − 181. doi: 10.6052/j.issn.1000-4750.2021.01.0090 XING Guohua, HUANG Jiao, LUO Xiaobao, et al. Crack calculation and analysis of concrete beams strengthened with near-surface mounted prestressed aluminium alloy bars [J]. Engineering Mechanics, 2022, 39(3): 171 − 181. (in Chinese) doi: 10.6052/j.issn.1000-4750.2021.01.0090

[31] 姚洁香, 董伟, 钟红. 岩石-混凝土界面拉伸断裂性能的率相关性研究[J]. 工程力学, 2022, 39(12): 108 − 119. doi: 10.6052/j.issn.1000-4750.2021.07.0532 YAO Jiexiang, DONG Wei, ZHONG Hong. Rate-dependency of tensile fracture properties of rock-concrete interface [J]. Engineering Mechanics, 2022, 39(12): 108 − 119. (in Chinese) doi: 10.6052/j.issn.1000-4750.2021.07.0532

[32] PAN B, QIAN K M, XIE H M, et al. Two-dimensional digital image correlation for in-plane displacement and strain measurement: A review [J]. Measurement Science and Technology, 2009, 20(6): 062001. doi: 10.1088/0957-0233/20/6/062001

[33] PAN B. Reliability-guided digital image correlation for image deformation measurement [J]. Applied Optics, 2009, 48(8): 1535 − 1542. doi: 10.1364/AO.48.001535

[34] PAN B. Digital image correlation for surface deformation measurement: Historical developments, recent advances and future goals [J]. Measurement Science and Technology, 2018, 29(8): 082001. doi: 10.1088/1361-6501/aac55b

[35] 苏勇, 张青川, 伍小平. 数字图像相关技术的一些进展[J]. 中国科学: 物理学 力学 天文学, 2018, 48(9): 29 − 53 SU Yong, ZHANG Qingchuan, WU Xiaoping. Progress in digital image correlation method [J]. Scientia Sinica (Physica, Mechanica & Astronomica), 2018, 48(9): 29 − 53.(in Chinese)

[36] 邵新星, 陈振宁, 戴云彤, 等. 数字图像相关方法若干关键问题研究进展[J]. 实验力学, 2017, 32(3): 305 − 325. doi: 10.7520/1001-4888-16-136 SHAO Xinxing, CHEN Zhenning, DAI Yuntong, et al. Research progress of several key problems in digital image correlation method [J]. Journal of Experimental Mechanics, 2017, 32(3): 305 − 325. (in Chinese) doi: 10.7520/1001-4888-16-136

[37] 熊二刚, 巩忠文, 罗佳明, 等. 基于数字图像相关技术的钢筋混凝土梁裂缝试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1094 − 1104. XIONG Ergang, GONG Zhongwen, LUO Jiaming, et al. Experiment on cracks in reinforced concrete beams based on digital image correlation technology [J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(4): 1094 − 1104. (in Chinese)

[38] 吴恺云, 罗素蓉, 郑建岚. 基于非接触式观测技术的再生骨料混凝土断裂性能分析[J]. 工程力学, 2022, 39(3): 147 − 157. doi: 10.6052/j.issn.1000-4750.2021.01.0067 WU Kaiyun, LUO Surong, ZHENG Jianlan. Fracture propertie analysis of recycled aggregate concrete based on digital image correlation technique [J]. Engineering Mechanics, 2022, 39(3): 147 − 157. (in Chinese) doi: 10.6052/j.issn.1000-4750.2021.01.0067

[39] 朱前坤, 王军营, 杜永峰, 等. 基于计算机视觉的结构应变无靶标鲁棒监测[J]. 建筑结构学报, 2023, 44(10): 211 − 221. ZHU Qiankun, WANG Junying, DU Yongfeng, et al. Unmarked robust monitoring of structural strain based on computer vision [J]. Journal of Building Structures, 2023, 44(10): 211 − 221. (in Chinese)

-

期刊类型引用(9)

1. 张宏杰,蔡养春,吴军强. 基于NSGA-Ⅱ算法的超声骨刀换能器设计与模态优化. 天津工业大学学报. 2025(02): 84-91 .  百度学术

百度学术

2. 周宇,陈卫星,赵现朝,高峰. 基于双层可展单元的空间伸展臂设计与分析. 机械设计与研究. 2024(02): 32-39 .  百度学术

百度学术

3. 欧阳衡,高硕,王世涛,马正琰,张德权. 基于子区间的雷达探测距离和测距精度分析. 工程设计学报. 2024(03): 332-339 .  百度学术

百度学术

4. 董朋虎,陈强,李彦斌,张旭东,马晗,费庆国. 基于自适应径向基网络的热防护结构可靠性评估. 工程力学. 2024(09): 234-244 .  本站查看

本站查看

5. 秦礼,房光强,郭俊康,曾令斌. 面向在轨组装的模组天线型面精度建模与调控算法研究. 航天制造技术. 2024(06): 1-9 .  百度学术

百度学术

6. 张纯,何君儒,周宇轩,林莹. 基于深度神经网络代理模型的盾构隧道密封垫断面优化. 工程力学. 2023(07): 137-144 .  本站查看

本站查看

7. 张凤玲,张旭,艾延廷,赵亚芝. 基于响应面法的高温应变计敏感栅结构优化研究. 仪器仪表学报. 2023(06): 144-155 .  百度学术

百度学术

8. 江春,范勤勤,韩新,王维莉,丛北华. 基于多核极限学习机的火灾代理模型研究. 制造业自动化. 2022(12): 39-44 .  百度学术

百度学术

9. 胡长明,操卫忠,孙为民,芮棽. 基于代理模型的车载雷达阵面风载疲劳分析. 强度与环境. 2020(04): 45-51 .  百度学术

百度学术

其他类型引用(8)

下载:

下载: