INVESTIGATION ON THE INFLUENCE OF WELDING PROCESSESON MECHANICAL PROPERTIES OF STAINLESS STEELFILLET WELD CONNECTIONS

-

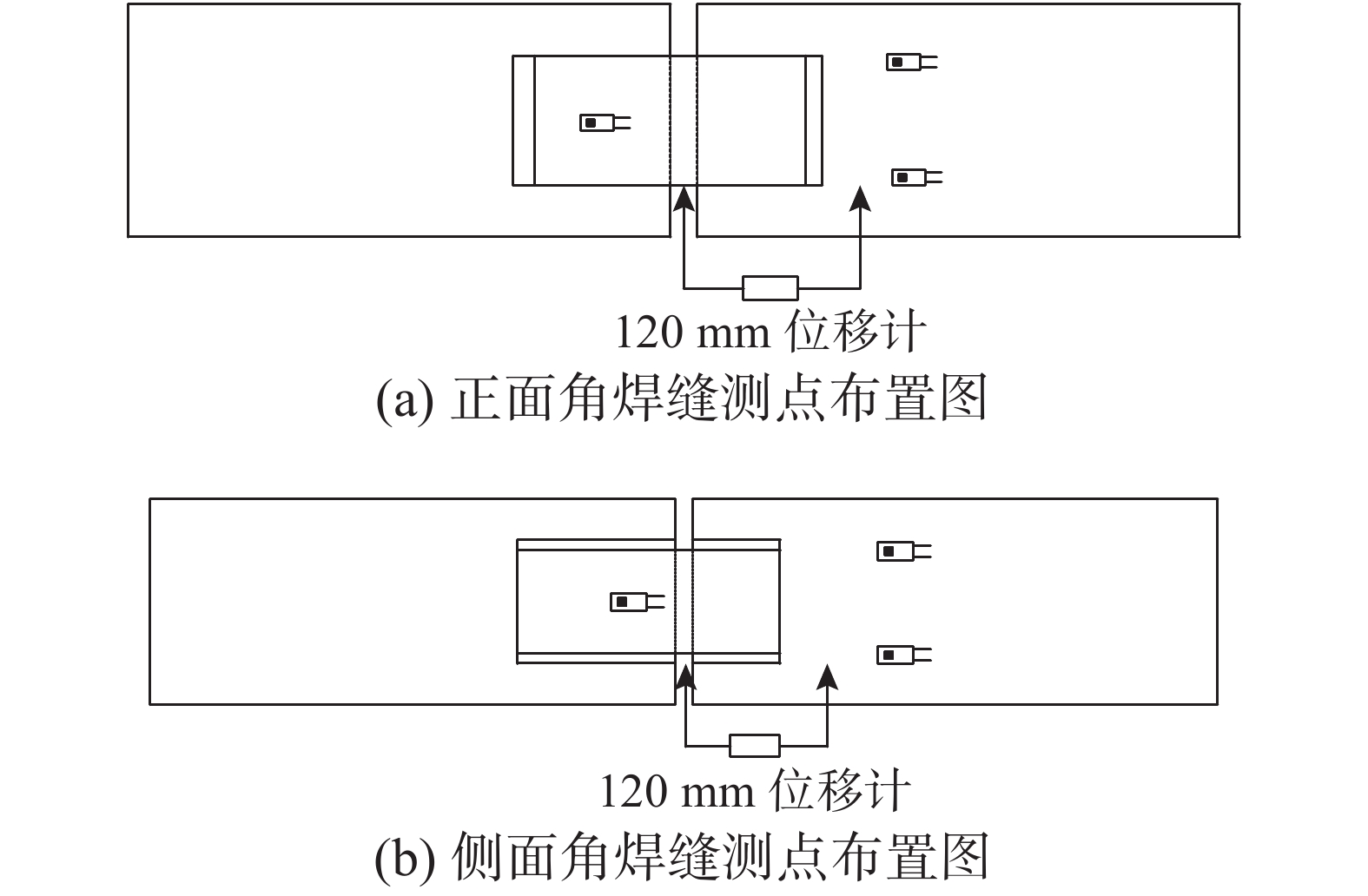

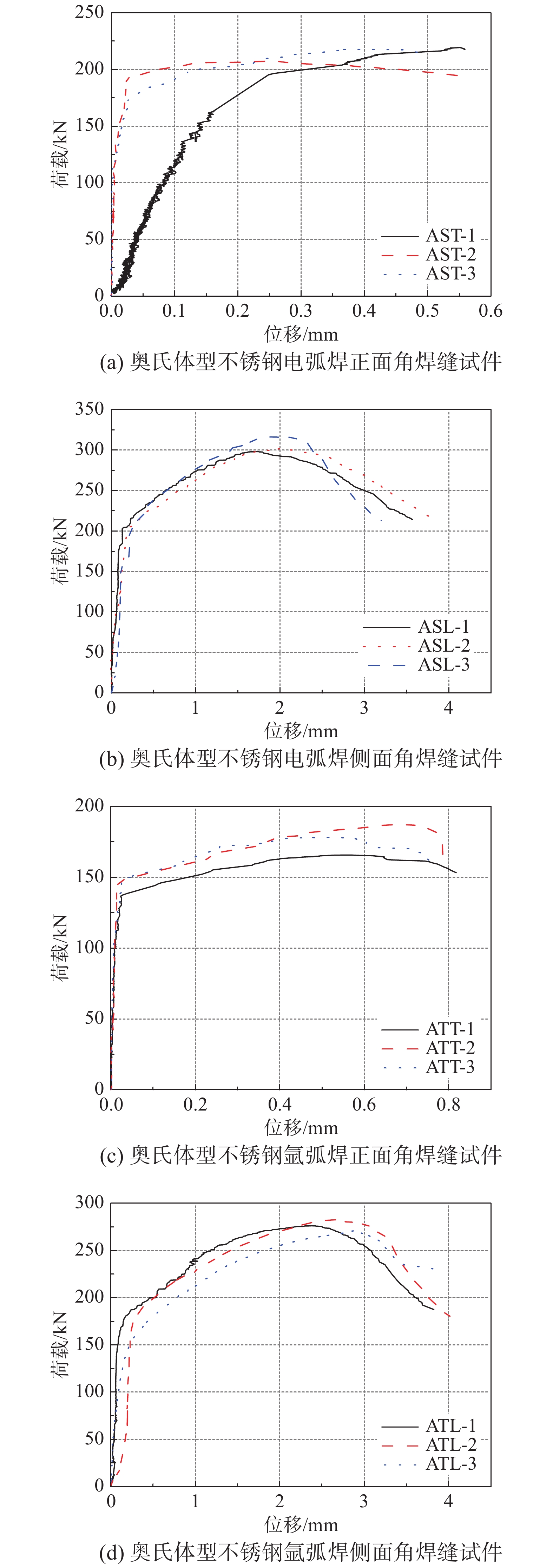

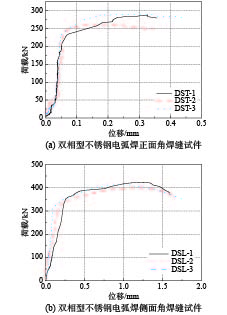

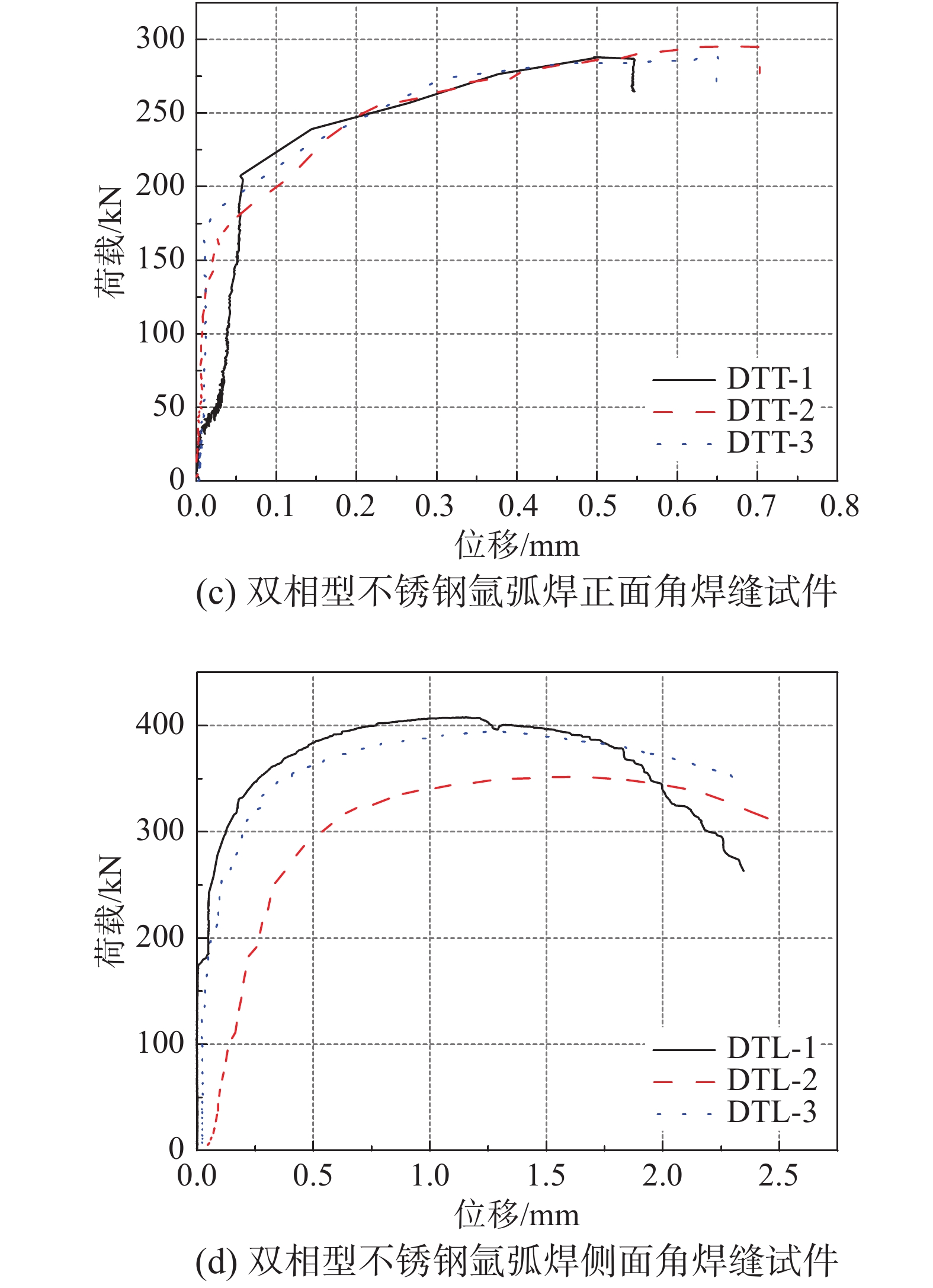

摘要: 对12个奥氏体型及12个双相型不锈钢正面角焊缝和侧面角焊缝连接试件进行了单调拉伸试验,考察了不同焊接工艺对角焊缝连接力学性能的影响。结果表明:采用氩弧焊焊接工艺的不锈钢角焊缝试件破坏面与电弧焊焊接工艺的试件破坏面形状相差较大,后者破坏面更加光滑;同时由于受到复杂应力的作用,正面角焊缝试件的真实破坏角度并不为相关规范规定的理论值45°;对于奥氏体型不锈钢角焊缝,氩弧焊试件与电弧焊试件的强度比分别为1.03 (正面角焊缝试件)及1.13 (侧面角焊缝试件),相对变形量之比为1.46及1.11;而对于双相型不锈钢角焊缝,两者的强度比分别为1.12和1.04,相对变形量之比为1.66及1.45;氩弧焊试件表现出了更好的力学性能。对于两种不锈钢材料,正面角焊缝强度均远大于侧面角焊缝的强度,建议在工程设计和相关规范的编制/修订中考虑正面角焊缝强度提高的影响。Abstract: In order to study the effect of different welding processes on mechanical properties of stainless steel fillet weld connections, the monotonic tensile tests of 12 austenitic and 12 duplex stainless steel specimens were carried out. The results show that the failure surface of specimens made by TIG (Tungsten Inert Gas Welding) is quite different from that of specimens made by SMAW (Shielded Metal Arc Welding), and the latter is much smoother. Besides, the true failure angle of the transverse fillet weld connections is not the theoretical value of 45° due to the influence of the complex stress. For austenitic stainless steel, the strength ratios of specimens made by TIG to SMAW are 1.03 (for transverse fillet weld connections) and 1.13 (for longitudinal fillet weld connections), and the ratios of relative deformation are 1.46 and 1.11. For duplex stainless steel, the strength ratios are 1.12 and 1.04, meanwhile the relative deformation ratios are 1.66 and 1.45. The connections made by TIG show better mechanical properties. For the two stainless steel, the strengths of transverse fillet weld connections are much better than those of the longitudinal fillet weld connections, so it is suggested that the influence of the increase of the strength of transverse fillet weld connections be taken into account in the compilation or revision of the related specifications.

-

-

表 1 试件实测尺寸

Table 1 Measurements of specimens

试件编号 焊缝

条数n焊缝平均

长度lw/mm焊缝平均焊脚

尺寸hf/mm焊缝平均断裂面

宽度he/mmAST-1 2 49.83 6.32 2.94 AST-2 49.63 5.80 3.16 AST-3 49.71 5.95 3.31 ATT-1 2 49.78 6.60 2.41 ATT-2 49.71 6.68 2.56 ATT-3 49.53 6.69 2.55 ASL-1 4 52.05 6.46 3.72 ASL-2 51.30 6.24 3.83 ASL-3 51.04 6.26 4.00 ATL-1 4 50.21 5.73 3.04 ATL-2 50.13 5.81 3.24 ATL-3 49.48 5.63 3.23 DST-1 2 49.98 6.06 3.17 DST-2 50.00 5.98 3.17 DST-3 49.76 5.98 2.84 DTT-1 2 49.89 6.04 3.32 DTT-2 50.43 5.94 2.60 DTT-3 50.16 6.03 2.62 DSL-1 4 50.96 5.96 3.53 DSL-2 50.57 6.14 3.57 DSL-3 50.59 5.98 3.56 DTL-1 4 50.76 5.87 3.32 DTL-2 50.14 5.72 3.01 DTL-3 50.69 5.86 3.25 表 2 角焊缝真实断裂角度

Table 2 Real fracture angle of fillet weld

电弧焊试件 试件破坏角度平均值θ/(°) 每组试件破坏角度平均值θavg/(°) 氩弧焊试件 试件破坏角度平均值θ/(°) 每组试件破坏角度平均值θavg/(°) AST-1 33.0 33.1 ATT-1 32.3 32.2 AST-2 32.9 ATT-2 31.8 AST-3 33.5 ATT-3 32.4 ASL-1 45.7 45.2 ATL-1 44.8 45.0 ASL-2 45.2 ATL-2 45.4 ASL-3 44.7 ATL-3 44.9 DST-1 32.0 32.5 DTT-1 32.3 32.9 DST-2 32.8 DTT-2 32.4 DST-3 32.6 DTT-3 33.9 DSL-1 45.0 45.6 DTL-1 45.0 45.8 DSL-2 45.2 DTL-2 46.9 DSL-3 46.6 DTL-3 45.6 表 3 奥氏体型不锈钢试件试验结果

Table 3 Test results of austenitic stainless steel specimens

试件编号 极限强度

τu-s/MPa平均极限强度

τu-s,avg/MPa相对变形量

δs平均相对

变形量δs,avg试件编号 极限强度

τu-t/MPa平均极限强度

τu-t,avg/MPa相对变形量

δt平均相对

变形量δt,avgτu-t,avg/

τu-s,avgδt,avg/

δs,avgAST-1 763.6 690.40 0.49 0.45 ATT-1 690.7 710.30 0.68 0.66 1.03 1.46 AST-2 660.5 0.46 ATT-2 735.0 0.66 AST-3 661.9 0.41 ATT-3 705.3 0.63 ASL-1 385.0 385.50 2.98 2.92 ATL-1 452.3 437.00 3.19 3.24 1.13 1.11 ASL-2 384.0 3.16 ATL-2 435.1 3.35 ASL-3 387.4 2.67 ATL-3 423.5 3.18 AST/ASL − 1.79 − 0.15 ATT/ATL − 1.62 − 0.20 − − 表 4 双相型不锈钢试件试验结果

Table 4 Test results of duplex stainless steel specimens

试件编号 极限强度

τu-s/MPa平均极限强度

τu-s,avg/MPa相对变形量

δs平均相对

变形量δs,avg试件编号 极限强度

τu-t/MPa平均极限强度

τu-t,avg/MPa相对变形量

δt平均相对

变形量δt,avgτu-t,avg/

τu-s,avgδt,avg/

δs,avgDST-1 909.3 920.70 0.30 0.32 DTT-1 869.8 1031.50 0.46 0.53 1.12 1.66 DST-2 828.3 0.29 DTT-2 1126.1 0.59 DST-3 1024.5 0.38 DTT-3 1098.6 0.54 DSL-1 587.9 571.70 1.33 1.39 DTL-1 605.0 595.30 1.96 2.01 1.04 1.45 DSL-2 553.1 1.37 DTL-2 582.8 2.10 DSL-3 574.0 1.47 DTL-3 598.2 1.97 DST/DSL − 1.61 − 0.23 DTT/DTL − 1.73 − 0.26 − − -

[1] Zheng B F, Shu G P, Jiang Q L . Experimental study on residual stresses in cold rolled austenitic stainless steel hollow sections [J]. Journal of Constructional Steel Research, 2019, 152: 94 − 104. doi: 10.1016/j.jcsr.2018.04.021

[2] 杨璐, 卫璇, 张有振, 等. 不锈钢母材及其焊缝金属材料单拉本构关系研究[J]. 工程力学, 2018, 35(5): 134 − 139. Yang Lu, Wei Xuan, Zhang Youzhen, et al. Research on the tensile stress-strain relation of stainless steel base material and its weld metal material [J]. Engineering Mechanics, 2018, 35(5): 134 − 139. (in Chinese)

[3] 常笑, 杨璐, 王萌, 等. 循环荷载下奥氏体型和双相型不锈钢材料本构关系研究[J]. 工程力学, 2019, 36(5): 137 − 147. Chang Xiao, Yang Lu, Wang Meng, et al. Study on constitutive model of austenitic stainless steel [J]. Engineering Mechanics, 2019, 36(5): 137 − 147. (in Chinese)

[4] 杨璐, 宁克洋, 班慧勇, 等. 不锈钢焊接箱形截面压弯构件弯曲屈曲试验研究[J]. 工程力学, 2018, 35(12): 143 − 150. Yang Lu, Ning Keyang, Ban Huiyong, et al. Experimental research on flexural buckling of stainless steel welded box-section beam-columns [J]. Engineering Mechanics, 2018, 35(12): 143 − 150. (in Chinese)

[5] 李华峰, 朱忠义, 束伟农, 等. 江门中微子实验中心探测器主体不锈钢结构设计研究[J]. 建筑结构, 2018, 48(20): 92 − 97. Li Huafeng, Zhu Zhongyi, Shu Weinong, et al. Design and research of the main stainless steel structure of the central detector of Jiangmen Underground Neutrino Observatory [J]. Building Structure, 2018, 48(20): 92 − 97. (in Chinese)

[6] 董彪, 罗建成, 魏峻峰, 等. “天衣无缝”的技艺设计—青岛胶东国际机场航站楼连续焊接不锈钢屋面应用分析[J]. 建筑技艺, 2019(4): 121 − 123. Dong Biao, Luo Jiancheng, Wei Junfeng, et al. A seamless heavenly robe of architecture technique: application analysis of continuously welded stainless steel roofing in Qingdao Jiaodong International Airport Terminal [J]. Architecture Technique, 2019(4): 121 − 123. (in Chinese)

[7] Butler L J, Kulak G L. Strength of fillet welds as a function of direction of load [J]. Welding Journal, 1971, 50(5): 231s − 234s.

[8] Miazga G S, Kennedy D J L. Behaviour of fillet welds as a function of the angle of loading [J]. Canadian Journal of Civil Engineering, 1989, 16(4): 583 − 599. doi: 10.1139/l89-089

[9] Ng A K F, Deng K, Grondin G Y, et al. Behavior of transverse fillet welds: Experimental program [J]. Engineering Journal-American Institute of Steel Construction Inc, 2004, 41(2): 39 − 54.

[10] 魏晨熙. Q460高强度钢材焊缝连接受力性能和计算模型研究 [D]. 北京: 清华大学, 2013. Wei Chenxi. Research on the structural performance and calculation model of Q460 high strength steel weld connection [D]. Beijing: Tsinghua University, 2013. (in Chinese)

[11] 孙铭泽, 张大长, 李布辉, 等. Q420 高强钢角焊缝承载力特性试验及模拟分析[J]. 南京工业大学学报: 自然科学版, 2014, 36(6): 99 − 103. Sun Mingze, Zhang Dachang, Li Buhui, et al. Test and simulation analysis on bearing capacity of Q420 high-strength steel fillet weld [J]. Journal of Nanjing Tech University (Natural Science Edition), 2014, 36(6): 99 − 103. (in Chinese)

[12] 范圣刚, 郑家珵, 孙文隽, 等. S30408奥氏体不锈钢高温力学性能试验研究[J]. 工程力学, 2017, 34(4): 172 − 181, 191. Fan Shenggang, Zheng Jiacheng, Sun Wenjun, et al. Experimental investigation on mechanical properties of S30408 austenitic stainless steel at elevated temperatures [J]. Engineering Mechanics, 2017, 34(4): 172 − 181, 191. (in Chinese)

[13] 袁焕鑫, 王元清, 石永久, 等. 焊接箱形截面不锈钢柱相关稳定性能分析[J]. 工程力学, 2015, 32(9): 84 − 91. Yuan Huanxin, Wang Yuanqing, Shi Yongjiu, et al. Behavior of interactive buckling in welded stainless steel box section columns [J]. Engineering Mechanics, 2015, 32(9): 84 − 91. (in Chinese)

[14] 金晓兰, 邹若梦, 董军. 不锈钢贴角焊缝连接试验及设计建议[J]. 建筑结构, 2013, 43(9): 78 − 82. Jin Xiaolan, Zou Ruomeng, Dong Jun. Experiments and design suggestions for stainless steel fillet connections [J]. Building Structure, 2013, 43(9): 78 − 82. (in Chinese)

[15] 杨璐, 张有振, 周晖, 等. 双相型S22053不锈钢角焊缝连接拉伸试验研究[J]. 土木工程学报, 2016, 49(11): 19 − 25. Yang Lu, Zhang Youzhen, Zhou Hui, et al. Tensile test study on fillet weld connections of S22053-grade duplex stainless steel [J]. China Civil Engineering Journal, 2016, 49(11): 19 − 25. (in Chinese)

[16] 张有振, 杨璐, 周晖, 等. 双相型不锈钢角焊缝连接承载性能有限元分析[J]. 工程力学, 2017, 34(9): 110 − 118. Zhang Youzhen, Yang Lu, Zhou Hui, et al. Finite element analyses of loading capacity of fillet-weld connections fabricated from duplex stainless steel [J]. Engineering Mechanics, 2017, 34(9): 110 − 118. (in Chinese)

[17] 杨璐, 张有振, 周晖, 等. 奥氏体型S30408不锈钢角焊缝连接拉伸试验研究[J]. 建筑结构学报, 2017, 38(2): 48 − 54. Yang Lu, Zhang Youzhen, Zhou Hui, et al. Tensile test on fillet weld connections of austenitic stainless steel grade S30408 [J]. Journal of Building Structures, 2017, 38(2): 48 − 54. (in Chinese)

[18] 张有振, 杨璐, 赵梦晗, 等. 奥氏体型S30408不锈钢角焊缝连接承载性能有限元分析[J]. 建筑钢结构进展, 2018, 20(1): 39 − 47, 72. Zhang Youzhen, Yang Lu, Zhao Menghan, et al. Finite element analysis of loading capacity of fillet weld connections fabricated using austenitic gradeS30408 stainless steel [J]. Progress in Steel Building Structures, 2018, 20(1): 39 − 47, 72. (in Chinese)

[19] Yang L, Cui Y, Wei X, et al. Strength of duplex stainless steel fillet welded connections [J]. Journal of Constructional Steel Research, 2019, 152: 246 − 260. doi: 10.1016/j.jcsr.2018.08.031

[20] 中国工程建设标准化协会. CECS 410: 2015, 不锈钢结构技术规程 [S]. 北京: 中国计划出版社, 2015. China Association for Engineering Construction Standardization. CECS 410: 2015, Technical specification for stainless steel [S]. Beijing: China Planning Press, 2015. (in Chinese)

[21] Lee H C, Hwang B K, Kim T S. Ultimate strength of austenitic stainless steel fillet-welded connections with weld metal fracture [J]. Thin-Walled Structures, 2017, 116: 145 − 153. doi: 10.1016/j.tws.2017.03.008

[22] SEI/ASCE 8-02, American society of civil engineers specification for the design of cold-formed stainless steel structural members [S]. Virginia: American Society of Civil Engineers, 2002.

[23] Fortan M, Dejans A, Debruyne D, et al. The strength of stainless steel fillet welds using GMAW [C]. Stainless Steel in Structures – Fifth International Experts Seminar, London, UK, 2017.

[24] EN 1993-1-4, Eurocode 3: Design of steel structures-part 1-4: General rules: Supplementary rules for stainless steel [S]. Brussels: European Committee for Standardization (CEN), 2006.

[25] 施刚, 陈玉峰. 高强度钢材焊缝连接试验研究[J]. 工业建筑, 2016, 46(7): 47 − 51. Shi Gang, Chen Yufeng. Investigation on high strength steel welded connections [J]. Industrial Construction, 2016, 46(7): 47 − 51. (in Chinese)

[26] 中华人民共和国住房和城乡建设部. GB 50017−2017, 钢结构设计标准 [S]. 北京: 建筑工业出版社, 2018. Ministry of Housing and Urban-Rural Development of the People's Republic of China. GB 50017−2017, Standard for design of steel structures [S]. Beijing: China Building Industry Press, 2018. (in Chinese)

-

期刊类型引用(9)

1. 刘旭宏,祁皑,罗才松,黄凯. 基于双重壳模型的钢筋黏结滑移有限元模拟. 工程抗震与加固改造. 2022(03): 23-29 .  百度学术

百度学术

2. 赵发军,李建. 基于ABAQUS的复合箍筋约束轻骨料混凝土柱偏压力学性能研究. 中国测试. 2022(09): 171-176+184 .  百度学术

百度学术

3. 陈宇良,朱玲,吉云鹏,吴辉琴,叶培欢. 三轴受压粉煤灰陶粒轻骨料混凝土力学性能试验. 复合材料学报. 2022(10): 4801-4812 .  百度学术

百度学术

4. 万宇通,郑文忠,王英. 网格箍筋约束混凝土柱轴压受力性能试验研究. 工程力学. 2022(11): 166-176 .  本站查看

本站查看

5. 牛建刚,许文明,梁剑. 受压区局部约束塑钢纤维轻骨料混凝土梁的抗弯性能. 材料导报. 2021(08): 8056-8063 .  百度学术

百度学术

6. 李磊,王卓涵,张艺欣,郑山锁. 混凝土结构中考虑滑移效应的钢筋本构模型研究. 工程力学. 2020(03): 88-97 .  本站查看

本站查看

7. 邓宗才,姚军锁. 高强钢筋约束超高性能混凝土柱轴心受压本构模型研究. 工程力学. 2020(05): 120-128 .  本站查看

本站查看

8. 赵恩亮. 不同侧向应力作用下轻骨料混凝土力学性能研究. 新型建筑材料. 2020(05): 17-21 .  百度学术

百度学术

9. 周天华,余吉鹏,李亚鹏,张钰. 单轴对称十字型钢混凝土短柱轴压性能试验研究. 工程力学. 2020(12): 157-170 .  本站查看

本站查看

其他类型引用(14)

下载:

下载: